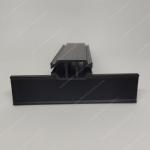

Extrusion PA66GF25 Thermal Break Insulation Strips For Aluminum Windows And Doors

|

Extrusion PA66GF25 Thermal Break Insulation Strips For Aluminum Windows And DoorsNylon Thermal Break Strip Advantages

The shape I thermal barrier polyamide strip can prevent the window frame from dust and water, has a better mechanical performance, is the first generation and easiest shape of insulating strips. For the shape I, we can provide the following size or customize according to customers’ requirements.

Characteristic of polyamide stripsPolyamide thermal breaks are extruded in dry state but they absorb moisture from the environment after the production as time passes. Moisture level depend the following conditions: - Ambient temperature - Ambient humidity - Storage period

During the summer time, when the temperature and humidity in storage area are higher than usual, the insulating profiles absorb more moisture than in the remaining seasons, even stored properly. What does a thermal break do?A thermal break is defined as a material with low thermal conductivity placed in an extrusion with the purpose of reducing the flow of thermal energy (heat). In aluminum windows, three types of thermal breaks are used. A standard pocket thermal break has been used in the window industry for decades.

DeliveryWe have the production capacity of 100000 meters per day. For common specifications, they will be shipped in 10-15 working days after payment. PackagesFor all shapes, they could be packaged in linear, the length will be 6 meters or customized. For the Shape "I", "C", and some simple shapes, they can be packed in rolls. 400-600 meters/roll. Product Performance

1. Sample water content less than 0.2% by weight. Our Service1. Expertise in the production of standard polyamide thermal break strips. 2. Respect customers' needs, provide customized products, try best to satisfy customers' requirements. 3. Fast service and on-time delivery 4. Strict quality control system, each production process will be strictly supervised by us. 5.We can provide all products on the insulation strip production line and the technical support. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: thermal insulating strut thermal glue strips 2mm Thickness Thermal Break Strips |

|

Polyamide Sound Insulation Extruding Profile Nylon Thermal Break Material Extrusion Strip |

|

Nylon Heat Insulation Strip Polyamide Extruding Profile Insert Into Aluminum Window |

|

Nylon Plastic Extrusion Profile Polyamide Heat Insulation Material Sound Insulation Strip |

|

PA66 GF25 Plastic Material Produce Thermal Break Strip Sound Insulation Profile |

|

Nylon Polyamide Products Extrusion With PA66GF25 Raw Material Heat Insulation Sound Insulation Profile |

|

Nylon Plastic Extrusion Profile Heat Insulation Products Insert Into Aluminum System Window |