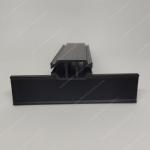

Customized Shape Nylon Pa66 Thermal Bridging Insulation Strip For Aluminum Window Profile

|

Customized Shape Nylon Pa66 Thermal Bridging Insulation Strip For Aluminum Window ProfileCharacteristic of polyamide stripsPolyamide thermal breaks are extruded in dry state but they absorb moisture from the environment after the production as time passes. Moisture level depend the following conditions: - Ambient temperature - Ambient humidity - Storage period

During the summer time, when the temperature and humidity in storage area are higher than usual, the insulating profiles absorb more moisture than in the remaining seasons, even stored properly.

What are the different types of thermal barriers?Currently, there are two principal types of thermal barriers: polyamide thermal barrier strip and pour & debridge (P&D). Our company only produce polyamide thermal barrier strip. Why do you need a thermal break?Why are thermal breaks important? Thermal breaks are essential for any external modern glazing system. Thermal bridging can be responsible for up to 30% of a property's heat loss. This lowers the homes energy efficiency, leading to higher heating bills.

What is the best thermal break?As an energy-saving, polyamide thermal break profile is the best thermal break material for aluminum profiles connections. Boasting high compressive strength, polyamide thermal break profile is a premier thermal bridging solution that won't compromise a structure's integrity.

Advantageshigh quality, competitive price, free sample support and short lead time, high mechanical strength, high toughness, high softening point, good wear resistance, self-lubrication, long-term work at higher temperatures, high CTI value, excellent electrical insulation, low smoke and toxicity characteristics. ApplicationIt is mainly used in insulation broken bridge aluminium products, helping to reduce heat loss or heat gain through the aluminum, and has better performance in terms of power usage.

Product Performance

1. Sample water content less than 0.2% by weight.

Package & DeliveryPackaging details: For all specifications, they could be packaged in linear, the length of each strip is usually 6 meters or customized. For the Shape "I", "C", and some simple shapes, they can be packed

in rolls. The length of each roll is usually 400-600 meters. shipped in 10-15 working days after receiving the deposit Our ServiceBefore sales 1. introduce products in detail During manufacturing 1. provide with layout and engineering conditions After Sales 1. provide installation, commissioning and training FAQ

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: thermal insulating strut thermal glue strips |

|

Polyamide Sound Insulation Extruding Profile Nylon Thermal Break Material Extrusion Strip |

|

Nylon Heat Insulation Strip Polyamide Extruding Profile Insert Into Aluminum Window |

|

Nylon Plastic Extrusion Profile Polyamide Heat Insulation Material Sound Insulation Strip |

|

PA66 GF25 Plastic Material Produce Thermal Break Strip Sound Insulation Profile |

|

Nylon Polyamide Products Extrusion With PA66GF25 Raw Material Heat Insulation Sound Insulation Profile |

|

Nylon Plastic Extrusion Profile Heat Insulation Products Insert Into Aluminum System Window |