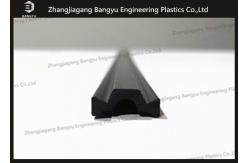

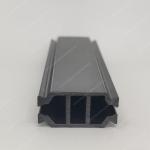

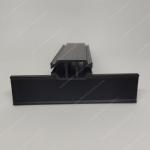

Extrusion PA66 GF25 Thermal Break Insulation Strips Used In Aluminium Window Frame

|

Extrusion PA66 GF25 Thermal Break Insulation Strips Used In Aluminium Window FrameWhat is a Thermal Barrier?Thermal barriers are made from resins that create a “thermal break” between the inner and outer surfaces of aluminum fenestration. Thermal barriers reduce heat loss or heat gain through the aluminum. Thermal barriers improve the U-value characteristics of finished systems. Thermal barriers are about energy conservation, U-values and government codes 70 percent of aluminum fenestration systems produced in North America contain a thermal break Primarily used in colder climates to reduce heat loss Increasing use of thermal barriers to reduce heat gain and also reduce heat loss Developers, architects and designers are demanding better performance in terms of power usage Stricter government regulations to reduce power usage in buildings to combat environmental concerns Aluminum, if it is to retain its market superiority in terms of its structural integrity, will have to achieve better performance in terms of U-values The use of thermal barriers will assist manufacturers to achieve improved LEED performance

What are the different types of thermal barriers?Currently, there are two principal types of thermal barriers: polyamide thermal barrier strip and pour & debridge (P&D). Our company only produce polyamide thermal barrier strip.

Package & DeliveryPackaging details: For all shapes, they could be packaged in linear, the length usually is 6 meters. Or we can customize based on customer's requirements. For the some simple shapes like 'I' shape and 'C' shape, they can

be packed in rolls. The length usually is 400-600 meters per roll. shipped in 10-15 working days after receiving the deposit

Characteristic of PA stripsAccording to different storage time and ambient climate, the dimension of PA strips will increase slightly because of the natural moisture absorption. And the mechanical properties will change slightly too. So, PA strips should be transported and stored under dry conditions away from the influence of weather. (rain, direct sunlight etc.)

Product Performance

1. Sample water content less than 0.2% by weight.

ApplicationIt is mainly used in insulation broken bridge aluminium products, helping to reduce heat loss or heat gain through the aluminum, and has better performance in terms of power usage.

Our ServiceBefore sales 1. introduce products in detail During manufacturing 1. provide with layout and engineering conditions After Sales 1. provide installation, commissioning and training

FAQ

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: thermal insulating strut thermal break polyamide strips |

|

Polyamide Sound Insulation Extruding Profile Nylon Thermal Break Material Extrusion Strip |

|

Nylon Heat Insulation Strip Polyamide Extruding Profile Insert Into Aluminum Window |

|

Nylon Plastic Extrusion Profile Polyamide Heat Insulation Material Sound Insulation Strip |

|

PA66 GF25 Plastic Material Produce Thermal Break Strip Sound Insulation Profile |

|

Nylon Polyamide Products Extrusion With PA66GF25 Raw Material Heat Insulation Sound Insulation Profile |

|

Nylon Plastic Extrusion Profile Heat Insulation Products Insert Into Aluminum System Window |