10 Micron Sintered Wire Mesh Pressure Resistant Plain Weave High Strength

|

|

High-strength pressure-resistant multilayer stainless steel sintered mesh

Product Description

The sintered web is made from one or more layers of woven wire mesh by a "sintering" process. The single layer woven wire mesh is first evenly flattened to ensure good contact at the intersection of the wires. The single or multiple layers of the calendered web are then laminated under mechanical pressure in a high temperature furnace by a special clamp filled with a proprietary embedded gas and the temperature is raised to the extent that sintering (diffusion bonding) occurs. After controlling the cooling process, the mesh becomes more rigid because all the contact points of the individual wires are bonded to each other. Sintering improves the properties of the woven wire mesh by a combination of heat and pressure. The sintered mesh may be a single layer or a plurality of layers, and a layer of perforated metal may be added to strengthen the entire structure according to filtration requirements. More importantly, the sintered mesh can be cut, welded, pleated, rolled into other shapes such as discs, plates, ink cartridges, and tapered. Compared with the traditional wire mesh, the sintered mesh has outstanding advantages, high mechanical strength, high permeability, reduced pressure, wide filter range and easy backwashing. Although the cost seems to be higher than the traditional filter, its long service life and excellent performance have gained more popularity and obvious advantages.

Our main products include

Five-layer sintered mesh Sintered mesh laminate Sintered mesh with perforated metal Sintered metal filter Sintered metal filter disk Folded sintered mesh filter Sintered cone filter Sintered metal fiber felt.

Product Feature

High mechanical stability High mechanical stability rating No displacement in the wire cloth structure High filtration capacity due to surface filtration Corrosion-resistant, wear-resistant, can work in the temperature range of -50 ° C to + 550 ° C. The sintered mesh can be made into a filter candle, a circle, a disk or the like as needed.

Specification list

Product Application

• High viscosity liquid filtration, such as polymers and adhesives

Product Parameters

|

|||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 10 micron sintered wire mesh pressure resistant sintered wire mesh high strength sintered stainless steel mesh |

|

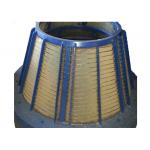

Conical Wedge Wire Basket With Technique Included Mine Selection Vibrating Screen |

|

0.25mm 0.5mm Slot Centrifuge Ss 304 Coal Centrifuge Basket For Mining Processing |

|

Industrial Centrifuge Stainless Steel Wire Mesh Wedge Wire Basket For Coal Mineral Screening And Dehydration |

|

Abrasion Resistant Wedge Wire Screen Basket Stainless Steel Johnson V Sieve |

|

High Density 316 211 Micron Dutch Stainless Steel Woven Wire Mesh |

|

Silver 316 Stainless Steel Woven Wire Mesh High Temperature Resistance |