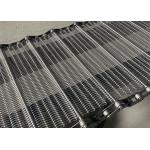

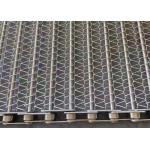

Conveying And Drying Food Chain Mesh Conveyor Belt , Construction

|

|

Conveying And Drying Food Chain Mesh Conveyor Belt For Construction

Chain Mesh Conveyor Belt Advantage:

Chain Mesh Conveyor Belt Classification:

Chain Mesh Conveyor Precautions:

(1) clean the sliding surfaces, screws, racks, gearboxes, oil holes, etc. of stainless steel mesh belts, free of oil, oil, or gas leakage from all parts of the equipment, and chips around Debris and dust. Mechanical engineers should clean them; (2) Neatly place tools, accessories and workpieces (products), and organize the pipeline. (3) Lubrication or timely oil change, continuous oil injection, no dry friction, normal oil pressure, varnish standard, smooth oil road, oil quality meets requirements, oil cup, linoleum clean; (4) safety follow safety operation regulations, do not use Overloaded equipment eliminates unsafe factors in a timely manner. The maintenance of food stainless steel conveyor belt generally includes daily maintenance, regular maintenance, regular inspection and accuracy check. Maintenance of equipment lubrication and cooling systems is also an important part of equipment maintenance.

Chain Mesh Conveyor Belt List

|

||||||||||

| Product Tags: mesh conveyor chain chain wire mesh |

|

1m 1.2m 1.5m Stainless Steel Chain Mesh Conveyor Belt Customization |

|

Stainless Steel SS304 Chain Link Spiral Wire Mesh Conveyor Belt For Food Grade Conveying Needs |

|

0.8-4mm Wire Diameter Chain Mesh Conveyor Belt 304 Stainless Steel |

|

Food Grade Anti Corrosive Chain Conveyor Belt Sample Available |

|

Food Grade 304 316 Chain Mesh Conveyor Belt For Industrial Production |

|

Anti Corrosive Food Grade Chain Link Conveyor Belt Width 30cm-4m |