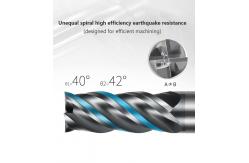

4 Flutes Customized Cutter Enhanced Performance With 38° Cutting Edge Angle

|

Product Description:Specialized Milling Cutters: Custom milling cutters can be designed

for specific machining operations, such as contouring, profiling,

or specialized surface finishes. These cutters may have unique

geometries, multiple cutting edges, or custom coatings to optimize

performance for a particular material or application. Applications:Custom tools designed for CNC working have a wide range of

applications across various industries where precise and

specialized machining operations are required. In the aerospace industry, for instance, engineers utilize custom

tools to machine complex components such as turbine blades,

aircraft structural parts, and engine components. These tools are

designed to meet stringent tolerances, optimize material removal

rates, and ensure accuracy in critical features. Customization:Are you looking for Custom End Mills for your business? We provide ODM/OEM Custom End Mills with ISO9001 certification. The minimum order quantity is only 5PCS, and the price can be negotiated. Our end mills come in single plastic tubes and can be delivered within 7-15 days. The payment terms are T/T,Paypal,Alipay. We have a large supply ability of 100000000000PCS. Our custom end mills are perfect for machining of high-hardness workpieces, and are compatible with Michael, Deckel, ANCA,TTB and TOP CNC machines. The workpieces can be carbon steels, alloy steels, stainless steels and copper alloy. We also provide customized cutters, non-standard machine tools and custom router bits. Support and Services:Technical Support and Services for Custom End Mills We understand that our custom end mills are a crucial part of our customers' operations. We strive to provide excellent customer service and technical support for all our products. Technical Support We have a team of experienced engineers and technicians who are available to answer technical questions and provide guidance on the use and application of our custom end mills. Our team is available via phone, email, or live chat to provide prompt and helpful assistance. Service and Maintenance We provide a wide range of services and maintenance options for our custom end mills. From routine maintenance to complex repairs, our team of technicians can help keep your custom end mills in optimal condition. We also offer on-site installation and training, as well as scheduled preventative maintenance services. Warranty We offer a limited warranty on all of our custom end mills. Our warranty covers defects in materials and workmanship and is valid for the duration of the warranty period specified on the product packaging. Please contact us if you have any questions about our warranty. Packing and Shipping:Custom End Mills packaging and shipping involves carefully

organizing and packing the product into a box or container,

depending on the size and weight of the item. The box or container

is then securely closed and labeled with the appropriate shipping

information. The package is then shipped via the most efficient

method, usually a carrier such as UPS or FedEx. FAQ:Q1:What is the Brand Name of the Custom End Mills?A1:The Brand Name of the Custom End Mills is ODM/OEM. Q2:What is the Model Number of the Custom End Mills? A2:The Model Number of the Custom End Mills is CUSTOM. Q3:Where is the Place of Origin of the Custom End Mills? A3:The Place of Origin of the Custom End Mills is Changzhou, Jiangsu, China. Q4:What is the Minimum Order Quantity of the Custom End Mills? A4:The Minimum Order Quantity of the Custom End Mills is 5PCS. Q5:What is the Payment Terms of the Custom End Mills? A5:The Payment Terms of the Custom End Mills is T/T,Paypal,Alipay. |

| Product Tags: Custom End Mills OEM 4 Flutes Customized Cutter Stainless Steel Customized Milling Cutters |

|

End Mills Shank Diameter Custom Made For Machining Hardness Workpieces Cutting Edge Angle 35/38/45/55 |

|

Cutting Edge Customized Type CNC Lathe Machining With OEM Support |

|

Custom End Mills Machining Hardness Workpieces Customized Overall Length Suitable For Stainless Steels |

|

Michael CNC Machining End Mills Customized Shank Diameter For Precision And Efficiency |

|

Carbide Custom End Mills 35 Helix Angle And 35 Cutting Edge Angle For Superior Results |

|

Transform Machining Process Custom End Mills For Precision Results |