Customize Your Machining with Varies Cutting Edge Material Carbide End Mill

|

Product Description:

Tungsten steel end mills are commonly used in machining operations

to remove material from a workpiece. They are capable of cutting

various materials, including metals, plastics, and composites. The

end mill consists of a cylindrical shank with cutting flutes along

its length and a cutting edge at the bottom. The number and

configuration of the flutes can vary depending on the specific

application.

The tungsten carbide material used in the end mill provides several

advantages over traditional high-speed steel (HSS) end mills. It

offers higher hardness, allowing for faster cutting speeds and

longer tool life. Tungsten carbide is also more resistant to heat

and wear, reducing the likelihood of tool failure and the need for

frequent tool changes.

Tungsten steel end mills are available in various types, such as

square end mills, ball nose end mills, and corner radius end mills,

among others. Each type has specific geometries designed for

different machining tasks and surface finishes.

When using a tungsten steel end mill, it's important to consider

factors like the material being machined, the cutting parameters

(e.g., cutting speed, feed rate), and the desired surface finish.

Proper tool selection and machining parameters contribute to

achieving optimal results and maximizing tool life.

It's worth noting that while tungsten steel end mills offer

excellent performance for many machining applications, they can be

brittle and prone to chipping if used improperly. Therefore, it's

important to follow recommended cutting guidelines and use

appropriate cutting fluid or lubrication to dissipate heat and

prolong tool life.

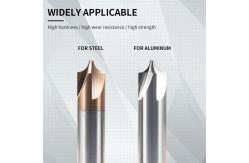

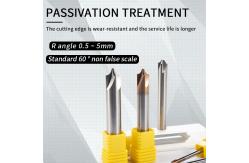

Features:Tungsten steel end mills, also known as tungsten carbide end mills, offer several advantages compared to other types of end mills, such as those made from high-speed steel (HSS). Here are some of the key advantages:

While tungsten steel end mills offer numerous advantages, it's important to note that they are relatively more brittle than HSS end mills. They should be used with proper cutting parameters and techniques to prevent chipping or breakage. Additionally, tungsten steel end mills are typically more expensive than HSS end mills, but their longer tool life and improved performance often justify the investment in many machining applications. Technical Parameters:When using tungsten steel end mills, it's important to consider the appropriate cutting parameters and techniques to achieve optimal results and maximize tool life. Here are some common cutting parameters and techniques to consider: Cutting Speed: The cutting speed is the surface speed of the cutting tool and is typically measured in meters per minute (m/min) or surface feet per minute (sfm). For tungsten steel end mills, higher cutting speeds can be employed compared to HSS end mills due to their superior heat resistance. However, the cutting speed should be within the recommended range for the specific material being machined to avoid excessive heat generation and potential tool wear. Feed Rate: The feed rate is the distance the cutting tool advances into the workpiece per revolution and is usually measured in millimeters per tooth (mm/tooth) or inches per tooth (ipt). The feed rate should be chosen based on the material being machined, the tool diameter, and the desired cutting forces. A proper feed rate helps maintain chip control, reduces tool wear, and prevents excessive tool deflection. Depth of Cut: The depth of cut refers to the axial depth of the tool's engagement with the workpiece. It is important to choose an appropriate depth of cut that balances material removal rate and tool life. A shallow depth of cut can reduce cutting forces and heat generation, while a deeper cut can increase productivity but may lead to higher cutting forces and tool wear. It's essential to consider the specific material and the capabilities of the machine tool when determining the depth of cut. Coolant/Lubrication: Using a suitable coolant or lubrication is crucial when machining with tungsten steel end mills. Coolant helps dissipate heat generated during cutting, prolongs tool life, and improves surface finish. It also aids in chip evacuation and reduces the risk of built-up edge formation. Depending on the machining operation and material being machined, different types of coolants or lubricants, such as water-soluble oils or cutting fluids, may be used. Tool Path and Machining Strategy: The tool path and machining strategy can have a significant impact on the performance and tool life of tungsten steel end mills. Using appropriate tool paths, such as climb milling or conventional milling, can help minimize tool deflection and vibration. Employing adaptive machining strategies or trochoidal milling can optimize tool engagement and chip evacuation, enhancing efficiency and reducing wear. Tool Holder and Machine Rigidity: The rigidity and stability of the tool holder and machine tool are vital for achieving optimal performance with tungsten steel end mills. A rigid setup helps minimize vibration, tool deflection, and chatter, leading to better surface finish and dimensional accuracy. It's essential to ensure proper tool holder selection, secure clamping, and adequate machine rigidity when using tungsten steel end mills. It is important to note that the cutting parameters and techniques can vary depending on the specific material being machined, the machine tool capabilities, and the desired machining objectives. Manufacturers' recommendations, cutting data charts, and consulting with tooling experts can provide valuable guidance for selecting appropriate cutting parameters and techniques for specific applications. Applications:Tungsten steel end mills are widely used in various machining applications across different industries. These end mills are known for their high hardness and wear resistance, making them suitable for a broad range of cutting and milling operations. Some common applications for tungsten steel mills include general milling, metalworking, aerospace industry, mold and die making, automotive industry, and woodworking and composites. General milling operations such as facing, profiling, slotting, and contouring can be easily accomplished with tungsten steel mills. They are also suitable for cutting and milling a wide range of metals, such as steel, stainless steel, aluminum, brass, and cast iron. The aerospace industry uses tungsten steel mills to create the precise features on components like aircraft parts, engine components, and structural elements. Mold and die makers rely on the high precision and surface finish of tungsten steel end mills to accurately machine complex shapes and contours on molds and dies. These end mills are also capable of machining tough materials like hardened tool steels used in mold and die production. Tungsten steel mills are a popular choice in the automotive industry, as they are able to remove material and create precise features on engine components, transmission parts, brake components, and other automotive components. For woodworking and composite materials applications, these end mills reliably cut wooden panels, doors, and furniture components, and additionally, are suitable for machining fiberglass, carbon fiber, and laminates. Customization:Customized Carbide End Mill Service We provide customized service of carbide end mill with the following features:

Our carbide end mill is ideal for cutting tools, milling cutter, router bits, drill bits, etc. Support and Services:Carbide End Mill provides technical support and services to customers. We offer free technical advice and assistance to help customers choose the right products for their application. Our customer service team is always available to answer any questions and provide helpful guidance. Our technicians are experienced in troubleshooting and resolving complex issues. We provide a warranty for our products and will replace any defective or damaged product. In addition, we offer a range of after-sales services including maintenance, repair, and replacement of parts. Packing and Shipping:Carbide End Mill packaging and shipping: FAQ:Q&A about Carbide End Mill

|

| Product Tags: Customize Carbide End Mill Machining Carbide End Mill |

|

SUPAL Tungsten Steel End Mill Router Bits Reamer For Versatile Cutting Applications |

|

Tungsten Steel End Mill With Versatile Cutting Edge Geometry And Coatings |

|

12 Shank1/2" Shank Round Over Rail Stile With Cove Panel Raiser 1Bit Router Bit Set Tenon Cutter For Woodworking Tools |

|

4.0mm Solid Carbide Tapered Ball Nose End Mill TiCN Coated CNC Milling Cutter Engraving Bit |

|

Solid Carbide Taper Ball Nose End Mill Router Bits Milling Cutters For Woodworking |

|

HRC68 Carbide End Mill Alloy Tungsten Steel Milling CNC Cutting Tools For SUS |