Polished Tungsten Carbide Strips With Thermal Conductivity 90-110

W/M·K And Fracture Toughness 9-11 MPa·M1/2

Product Description:

Tungsten Carbide Strips are made of cemented carbide, also known as

carbide wear strips, which is a composite material made of hard

carbide and a softer metal binder, usually cobalt or nickel. It is

characterized by its hardness, wear resistance, thermal

conductivity, and compressive strength. The thermal conductivity of

Tungsten Carbide Strips is between 90-110 W/m·K. The compressive

strength of Tungsten Carbide Strips is from 4000 to 4500 MPa,

making them suitable for applications that require high wear

resistance, such as cutting tools. The surface roughness of

Tungsten Carbide Strips is Ra 0.4. These Tungsten Carbide Strips

are widely used in many industries, such as automotive, aerospace,

and medical industries.

Features:

- Product Name: Tungsten Carbide Strips

- Compressive Strength: 4000-4500 MPa

- Thermal Conductivity: 90-110 W/m·K

- Color: Silver Gray

- Surface Roughness: Ra 0.4

- Density: 14.9-15.1 G/cm3

- Highly wear resistant

- Excellent corrosion resistance

- High hardness and strength

- Good heat conductivity and stability

- Ideal choice for carbide wear strips, carbide wear strips, cemented

carbide strips and tungsten carbide strips.

Technical Parameters:

| Product Attributes | Technical Parameters |

|---|

| Material | Tungsten Carbide |

| Compressive Strength | 4000-4500 MPa |

| Tensile Strength | 1800-2100 MPa |

| Density | 14.9-15.1 G/cm3 |

| Color | Silver Gray |

| Surface Roughness | Ra 0.4 |

| Size | Customized |

| Bending Strength | 2500-3000 MPa |

| Shape | Strip |

| Fracture Toughness | 9-11 MPa·m1/2 |

Applications:

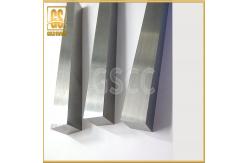

Gold Sword tungsten carbide strips are widely used in cutting tools

due to their high wear resistance and strength. Cemented carbide

strips from Gold Sword are composed of tungsten carbide and cobalt.

The tungsten carbide provides excellent hardness and wear

resistance, and the cobalt provides excellent bond strength and

toughness. The combination of tungsten carbide and cobalt provides

superior wear resistance and impact resistance, making Gold Sword

tungsten carbide strips an ideal choice for applications that

require superior cutting performance. The Gold Sword tungsten

carbide strips also have excellent thermal conductivity, high

temperature resistance, and low thermal expansion coefficient,

which make them suitable for a variety of cutting tools. The

surface finish of Gold Sword tungsten carbide strips is polished,

providing a smooth surface finish that can reduce friction and

improve cutting performance. The density of Gold Sword tungsten

carbide strips is 14.9-15.1 g/cm3, and the thermal expansion

coefficient is 4.5-5.5×10-6/K. The thermal conductivity of Gold

Sword tungsten carbide strips is 90-110 W/m·K. Gold Sword tungsten

carbide strips are certified by ISO9001, and they are available in

a variety of sizes and shapes. The minimum order quantity of Gold

Sword tungsten carbide strips is 1pcs, and the delivery time is

15-20 days. Prices are negotiable, and the packaging is paper

boxes, wooden boxes, carton, and iron barrel. Gold Sword provides a

reliable supply of tungsten carbide strips with a capacity of up to

50000pcs/month.

Packing and Shipping:

We package and ship Tungsten Carbide Strips with the highest

quality standards to ensure all products arrive at their

destination in perfect condition. Our packaging process includes

the following steps:

- We wrap the product in protective plastic wrap to protect it from

moisture, dust, and other contaminants.

- We place the product into a custom-made cardboard box to ensure a

secure fit.

- We place the box into a larger cardboard box with padding to

provide extra protection.

- We seal the box with packing tape to prevent any tampering.

- We label the box with the customer's shipping address.

- We ship the package via a reliable carrier to ensure timely and

safe delivery.

FAQ:

.