Woodcutting Tungsten Carbide Strips With HIP Sintering RX10 / RX20 / RX10T / AB10

|

|

Woodcutting Tungsten Carbide Strips With HIP Sintering RX10 / RX20 / RX10T / AB10

Introduction of Tungsten Carbide Strips

1. Used for woodcutting 2. Size: can be customized 3. With high hardness 4. Easy brazing 6. Manufactory price 7. Fast delivery

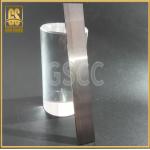

Tungsten Carbide Strips Benefits

* Substantially longer service life than traditional steel tools * Consistent working depth and tillage quality * Permanently sharp cutting edges mean improved heeling and less traction power required * Needs no depth adjustment due to wear * Saves time and money thanks to fewer blade changes * Much longer periods of use during good weather * Optimum utilization of machine power * Lower tool costs per acre * Money saved through reduced stocks

Note: Our company can produce alloy grades that are more suitable for special processing fields according to customer needs.

Advantages

1. Strict tolerance ranges makes high precision |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: square carbide blanks cemented tungsten carbide | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Chemical Fiber Cutting Carbide Wear Strips with Excellent Wear Resistance |

|

Cutting Tools Cemented Carbide Strips For Industrial Applications |

|

Customized Tungsten Carbide Strips 90-110 W/M·K Thermal Conductivity |

|

High Compressive Strength Carbide Wear Strips 4000-4500 MPa Bending Strength 2500-3000 MPa |

|

High Tensile Strength Tungsten Carbide Strips With Density 14.9-15.1 G/Cm3 |

|

Silver Gray Tungsten Carbide Strips With Tensile Strength 1800-2100 MPa |