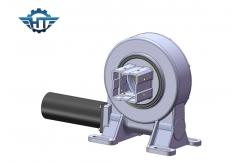

Ve7 Worm Gear Slew Drive For Horizontal Solar Tracking System

|

|

VE7 Worm Gear Slew Drive for Horizontal Solar Tracking System

VE7 Slew Drive Gearbox Description

A slewing gearbox, also known as a slew drive or slewing ring, is a mechanical device used to provide rotational movement or slewing motion to heavy machinery and equipment. It is commonly employed in applications that require controlled rotation, such as cranes, excavators, wind turbines, and solar trackers. The slewing gearbox consists of several key components: Outer Ring: The outer ring serves as the stationary part of the gearbox and provides a stable mounting surface. It is typically circular in shape and incorporates a series of gear teeth or raceways on its inner circumference. Inner Ring: The inner ring is connected to the equipment or machinery that requires slewing motion. It is mounted on the outer ring and is designed to rotate relative to it. The inner ring also features gear teeth or raceways on its outer circumference. Gear Mechanism: The gear mechanism enables the rotation of the inner ring relative to the outer ring. It typically consists of a set of gears or rollers that engage with the teeth or raceways on both the inner and outer rings. By transmitting torque and reducing friction, the gear mechanism allows smooth and controlled slewing motion. Drive System: The drive system is responsible for providing power to the slewing gearbox. It can be powered by various means, including electric motors, hydraulic systems, or gear motors. The drive system transfers rotational energy to the gear mechanism, initiating the slewing motion. Bearings: Slewing gearboxes incorporate bearings to support the load and minimize friction during rotation. These bearings are designed to withstand high axial, radial, and moment loads, ensuring the gearbox's stability and durability. Sealing and Lubrication: To protect the internal components from contaminants and maintain smooth operation, slewing gearboxes are equipped with sealing systems. These seals prevent dust, moisture, and other particles from entering the gearbox. Lubrication is also essential to reduce friction and wear between moving parts, prolonging the lifespan of the gearbox.

Technical Data of Vertical Single Series Slewing Drives

Applications Slewing gearboxes are engineered to provide precise and controlled slewing motion, allowing heavy equipment to rotate horizontally or vertically. They are designed to withstand heavy loads, harsh environmental conditions, and continuous operation, making them crucial components in various industrial and construction applications.

Glossary of Key Paramaters

Tilting Moment Torque: This torque is the gravity load multiplied by distance between the position of load and the center of slewing bearing. If the actual torque is greater than the rated tilting moment torque, slewing drive will be overturned. Radial load: The load vertical to the axis of slewing bearing Axial load: The load parallel to the axis of slewing bearing Holding torque: It is the reverse torque.When the drive is rotating reversely, and parts are not damaged,The maximum torque achieved is called holding torque, it is also seen as broken torque. Self-locking: Only when there is load, the slewing drive is not able to reverse rotate and thus called self-locking.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ve7 worm gear slew drive high efficiency worm gear slew drive ve7 solar tracker slew drive |

|

|

12V-380V Solar Tracker Slew Drive With IP66 Protection For PV Tracking System |

|

|

24VDC Solar Tracking Rack System Slew Motor With Single Axis / Dual Axis Drive |

|

|

Single Axis Slew Drive Gearbox With Electrical Motor For PV Mounting Tracking System |

|

|

VE Series Slewing Drive For High Precision And Absolute Reliability In Solar Tracking |

|

|

VE9 Slew Drive Gearbox For Oblique Or Tilted Horizontal Single Axis Solar Tracking System |

|

|

VE7 Vertical Single Axis Solar Tracking Slewing Drive Gearbox For Solar Tracking System |