Precision Injection Molding Tooling Long Life 1 Million Shots Cold Runner

|

|

Plastic Injection Mould

1, Design conside all details, such as plastic part order quantity, part structure, injection cycle, tolerance, manufacture cost and so on

2, To choose the reasonable mould steel and provide steel material report

3, Manufacture, quality inspection each step, provide mould making schedule and update weekly

4, Mould Trial report and samples sent for approval

5, To provide some wearing parts packed together with mould in wooden carton for shipment

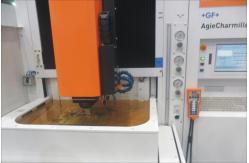

JZY Equipments

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: plastic injection mold tooling plastic injection tooling | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Single Cavity Plastic Injection Molded Parts Automobil Decoration IS09001 Approval |

|

High Precision Injection Molding Tooling Plastic LKM Base 300000 Shots Mould Life |

|

Two Cavities Injection Molding Components Mold Part Processing Customized Size |

|

Customzed Plastic Injection Mold Tooling , Plastic Molding Parts LKM Mould Base |

|

Cold Runner Injection Molding Tooling 8 Cavity Mirror / Polishing Surface |

|

Polishing Surface Professional Plastic Mold Injection , Injection Mold Design 2 Cavity |