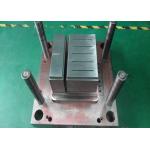

Hot / Cold Runner Custom Injection Molding Texture / Mirror Polishing

|

Detailed Product Description

|

Precision Injection Mould

1, Design conside all details, such as plastic part order quantity, part structure, injection cycle, tolerance, manufacture cost and so on

2, To choose the reasonable mould steel and provide steel material report

3, Manufacture, quality inspection each step, provide mould making schedule and update weekly

4, Mould Trial report and samples sent for approval

5, To provide some wearing parts packed together with mould in wooden carton for shipment

JZY Equipments

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: injection mould tool custom injection molding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Related Products

|

High Precision Injection Mould 1 Million Shots Long Life S136 Steel Materials |

|

Mirror Polishing Precision Injection Mould for Clear Container , HASCO Standard |

|

DME Standard Injection Mould Tool For Medical Health Product 4 Cavity Mold |

|

52 HRC High Performance Multi Cavity Molds ISO Approved With S136 Materials |

|

50 HRC Customized Precision Injection Mould 500k Cycles Life , Home Appliance Mould |

|

Customized Plastic Injection Mould With Precision Tolerance OEM / ODM Service |

Email to this supplier