UV / IR Grade Quartz Through Hole Plates Custom Cut High Temperature Chemical

|

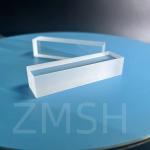

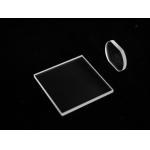

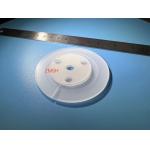

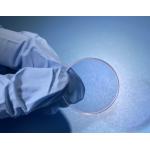

Overview of Quartz PlateQuartz plates with through-holes are engineered components fabricated from high-purity silica glass, available in custom dimensions and complex geometries. These shaped quartz substrates are designed to support high-performance applications in optics, microfluidics, vacuum systems, and high-temperature manufacturing. The integrated holes allow for beam alignment, gas flow, fiber feedthroughs, or mounting functions. The plates are offered in various material types to match spectral and thermal needs.

Quartz Material Types Explained of Quartz Plate

How They’re Made of Quartz PlateLaser drilling is a high-precision, non-contact method used to create holes in fused quartz glass by focusing a concentrated laser beam on the material surface. The intense energy of the laser rapidly heats and vaporizes the quartz, forming clean holes without causing cracks or mechanical stress. This technique is especially suitable for microholes (as small as 10 microns), high-density patterns, and fragile quartz components. Femtosecond or picosecond lasers are commonly used to minimize heat-affected zones and achieve smooth edges with excellent accuracy. Laser drilling is widely applied in microfluidics, semiconductors, optics, and advanced scientific instruments that require precision and reliability.

Use Cases of Quartz PlateDrilled fused quartz glass, featuring precision microholes, through-holes, or complex patterns, is widely used in high-tech industries due to its outstanding thermal stability, optical transparency, and chemical resistance. The ability to introduce custom hole geometries expands the material’s functionality, making it a key component in numerous advanced applications. 1. Semiconductor ProcessingDrilled quartz substrates are used in:

2. Microfluidic DevicesFused quartz with microholes is ideal for:

3. Optics & PhotonicsQuartz’s high UV and IR transmission makes it valuable in:

4. High-Temperature and Vacuum SystemsDrilled quartz components are used in:

5. Chemical and Pharmaceutical IndustryQuartz's chemical inertness makes it perfect for:

6. Aerospace and DefenseSpecialized quartz parts with precision holes are used in:

7. Scientific Research & Custom LabwareMany universities and research institutions use drilled quartz glass in:

FAQ of Quartz PlateQ1: Do you offer double-side polishing for these plates?

Q2: What’s the typical thickness range?

Q3: Can you process complex shapes like notches or slots?

Q4: Is JGS3 suitable for laser use?

Quartz Glass Window UV Fused Silica Optical Viewport Custom Size Coating Available Custom Irregular-Shaped Quartz Optical Windows Precision Fused Silica Viewports

About Us

ZMSH specializes in high-tech development, production, and sales of special optical glass and new crystal materials. Our products serve optical electronics, consumer electronics, and the military. We offer Sapphire optical components, mobile phone lens covers, Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor crystal wafers. With skilled expertise and cutting-edge equipment, we excel in non-standard product processing, aiming to be a leading optoelectronic materials high-tech enterprise.

Packaging & Shipping Information

Packaging Method:

Shipping Channels & Estimated Delivery Time:

UPS, FedEx, DHL

|

| Product Tags: UV IR Grade Quartz Plates Custom Cut Quartz Plates |

|

Sapphire Optical Lenses AL2O3 Customizable High Temperature Resistance DSP 60/40 |

|

Sapphire Lift Pin AL2O3 0.4mm-30mm Customizable Wear And High Temperature Resistance |

|

Quartz Optical Window BF33 Sapphire Substrate JGS1 JGS2 Fused Silica Quartz Plate |

|

K9 Sapphire Quartz Optical Windows ZnSe Wafer Windows Laser Optical Glass |

|

Al2O3 Single Crystal Sapphire Glass Razor Blade Medical Sharp And Polished 38x4.5x0.3mmt |

|

High Resistant Sapphire Crystal Parts Blue Red Clear AR Coating Parts |