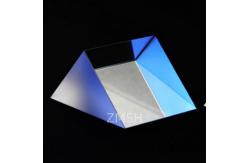

Fused Quartz Optical Prisms UV/VIS Transmission Custom AnglesDefinition of Fused Quartz Optical PrismsA prism is an optical element in which one or more reflective

surfaces are ground into a single piece of glass. It functions to

redirect light paths, invert or rotate images, and can be

considered as a combination of planar mirrors. Prisms are widely

used in laser research, laser optical systems, optical imaging,

machine vision, life sciences, and biomedical applications or

products. Prisms can not only deflect light but also adjust image

orientation. The design of a prism determines how it interacts with

light. When light enters a prism, it may reflect off one or more

surfaces before exiting, or it may be refracted as it passes

through the prism.

Features of Fused Quartz Optical Prisms | Type | Features |

|---|

| Right-Angle Prism | 1. Deviates light path by 90° or 180°

2. Used in image/light path redirection | | Wedge Prism | 1. When used alone, deflects the beam by a specific angle

2. When used in pairs, enables beam shaping or deviation control | | Pentaprism | 1. Deviates light path by 90°

2. Maintains image orientation without inversion or reflection | | Dove Prism | 1. Rotates the image by twice the prism’s rotation angle

2. Output beam remains aligned with the original beam direction | | Hollow Roof Mirror (Reflective) | 1. Deviates light path by 180°

2. Reflective surface is coated with aluminum |

Description of Fused Quartz Optical Prisms 1. Right-Angle PrismA right-angle prism is commonly used to redirect the light path or

deflect the image formed by an optical system by 90°. Depending on

the orientation of the prism, the resulting image may appear

laterally correct but vertically inverted. Right-angle prisms are

also applied in image combination and beam displacement. When light enters through one of the right-angle faces, it

undergoes total internal reflection at the hypotenuse surface

(interface with air) and exits through the other right-angle face,

resulting in a 90° deviation.

When light enters through the hypotenuse surface, it experiences

total internal reflection at both right-angle faces (interfaces

with air) and exits back through the hypotenuse after being

deviated by 180°. 2. Wedge PrismWhen used individually, a wedge prism can deflect a normally

incident light beam on its vertical surface by a certain angle. The

deflection angle depends on the wedge angle—different wedge angles

result in different beam deviations. When the beam remains

stationary and the wedge prism is rotated, it can produce a

circular scanning output of the beam. A pair of wedge prisms can steer the beam to any position within a

full-angle 4θd circle, where θd is the deviation angle of a single

prism. This beam steering is achieved by independently rotating the

two wedge prisms. It is commonly used in imaging applications to

scan the beam to various positions, enabling precise beam control. 3. PentaprismA pentaprism reflects incoming light twice within the prism,

changing its direction by exactly 90°. The image remains upright

and retains its original handedness (no inversion or mirroring).

Compared to a single-reflection right-angle prism, a pentaprism can

precisely deflect the incoming beam by 90°, regardless of the

prism's mounting orientation. This makes it more stable than a

system composed of two mirrors, as it eliminates sensitivity to the

angle of incoming light. As a result, pentaprisms are commonly used in various optical

observation and calibration instruments, such as theodolites,

collimators, and rangefinders. In DSLR cameras, the viewfinder's

reflex system also uses a pentaprism to redirect the optical path

at a fixed angle. 4. Dove PrismThe Dove prism has unique optical properties. When light enters

from the slanted face, the output beam maintains its original

direction but forms an inverted image. If the prism is rotated by

an angle θ, the resulting image rotates by 2θ. When light enters

from the bottom surface of the prism, the beam is reflected back in

the opposite direction, also producing an inverted image. The Dove prism performs best when used with collimated (parallel)

light. If the incoming beam is convergent, astigmatism may be

introduced, which degrades image quality. Additionally, because

total internal reflection occurs within the Dove prism, a phase

difference arises between the s- and p-polarized components, which

can affect the polarization state of the transmitted beam. 5. Hollow Roof Mirror PrismThe hollow roof mirror prism reflects light that enters from the

slanted surfaces of the prism. Unlike flat mirrors, the reflected

beam remains parallel to the incident beam but is laterally

displaced, avoiding issues caused by beam interference. The two angled surfaces of the right-angle prisms are fixed at a

precise angle, making the setup much more convenient and accurate

compared to manually aligning two separate mirrors to achieve

parallel beam reversal.

Applications of Fused Quartz Optical Prisms Quartz prisms are widely used in precision optical systems due to

their excellent UV transmission, thermal stability, chemical

resistance, and low birefringence. Their ability to precisely

manipulate light paths through refraction and reflection makes them

ideal for high-performance optical applications. Key application

areas include: 1. Laser and Optical Systems- Used to redirect, split, or combine laser beams with high precision

- Ideal for high-power laser systems due to quartz's high damage

threshold

- UV-grade quartz prisms are essential in excimer laser setups and

beam steering assemblies

2. Spectroscopy and Analytical Instruments- Serve as dispersive elements in spectrometers for separating

wavelengths

- UV-transparent quartz prisms are used in fluorescence and

absorption spectroscopy

- Enable precise angle-dependent analysis of optical signals in

scientific instruments

3. Imaging and Vision Systems- Correct and manipulate image orientation in microscopes, cameras,

and telescopes

- Employed in pentaprisms, right-angle prisms, and Dove prisms for

image rotation or redirection

- Common in machine vision, biomedical imaging, and inspection

systems

4. Photonics and Communication- Quartz prisms serve as polarization rotators, beam steering

elements, or wavelength separators in fiber optic and photonic

circuits

- Used in the design of optical isolators and modulators due to

quartz’s stable refractive index

5. Metrology and Alignment Tools- Integrated into autocollimators, alignment scopes, and surveying

instruments for accurate angle measurement and beam deviation

- Provide reliable reference angles in interferometry and calibration

systems

6. Aerospace and Harsh Environment Optics- Quartz prisms operate reliably in vacuum, high-radiation, and

high-temperature environments

- Used in satellite imaging, spaceborne spectroscopy, and defense

optics systems

FAQ of Fused Quartz Optical PrismsQ1: What is a quartz prism and how is it different from standard

glass prisms?

A1:

A quartz prism is an optical prism made from high-purity

crystalline or fused quartz (SiO₂), known for its excellent UV

transmission, thermal stability, and chemical resistance. Compared

to standard glass prisms (e.g., N-BK7), quartz prisms can operate

in deeper UV ranges, withstand higher temperatures, and are more

suitable for harsh or high-energy environments. Q2: What wavelength range can quartz prisms transmit?

A2:

Quartz prisms offer a wide transmission range, typically from 180

nm (deep UV) to 2.2 μm (near-infrared). This makes them ideal for

ultraviolet lasers, fluorescence spectroscopy, and IR beam

steering. Q3: Are quartz prisms resistant to high temperatures?

A3:

Yes. Quartz has a high thermal stability with a softening point

around 1,620°C and excellent resistance to thermal shock. This

makes quartz prisms suitable for high-power laser optics and

high-temperature measurement systems. Related products

Quartz Glass Window UV Fused Silica Optical Viewport Custom Size

Coating Available Quartz Prisms UV Grade Beam Steering Optics for Laser and Imaging

Systems About Us ZMSH specializes in high-tech development, production, and sales of

special optical glass and new crystal materials. Our products serve

optical electronics, consumer electronics, and the military. We

offer Sapphire optical components, mobile phone lens covers,

Ceramics, LT, Silicon Carbide SIC, Quartz, and semiconductor

crystal wafers. With skilled expertise and cutting-edge equipment,

we excel in non-standard product processing, aiming to be a leading

optoelectronic materials high-tech enterprise. Packaging & Shipping Information Packaging Method: - All items are securely packed to ensure safe transit.

- Packaging features anti-static, shock-resistant, and dust-proof

materials.

- For sensitive components such as wafers or optical parts, we adopt

cleanroom-level packaging:

- Class 100 or Class 1000 dust protection, depending on product

sensitivity.

- Customized packaging options are available for special

requirements.

Shipping Channels & Estimated Delivery Time: - We work with trusted international logistics providers, including:

UPS, FedEx, DHL - Standard lead time is 3–7 business days depending on the

destination.

- Tracking information will be provided once the order is dispatched.

- Expedited shipping and insurance options are available upon

request.

|