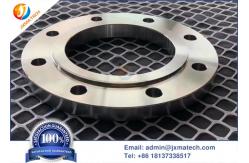

Titanium Grade 2 Flanges

|

|

Titanium Grade 2 Flanges ASTM B381 Titanium Grade 2 Flanges is mainly made of metal titanium through forging process, which further improves the mechanical properties and tensile strength of the flange. Titanium Flanges are mainly used as interface components in the connection of key pressure parts in oil drilling, offshore engineering, and machinery and equipment manufacturing.Titanium Grade 2 Flanges Forging is a plastic forming process that uses the plasticity of metals to obtain certain shape and structural properties of blank materials under the impact or pressure of tools. The advantage of its production is that it can not only obtain the shape of mechanical parts, but also improve the internal structure of materials and improve the mechanical properties of mechanical parts. Features of Titanium Grade 2 Flanges: 1. High dimensional accuracy, light weight, high strength, excellent surface finish 2. High tensile strength, excellent acid and alkali resistance, strong wear resistance 3. Long service life, good environmental protection and high cost performance Types of ASTM B381 Titanium Flange: 1. Titanium blind flange (for pressure testing of pipeline equipment) 2. Titanium flat welding flange (suitable for high temperature and high pressure environment) 3. Titanium lap flange (commonly used for pipeline inspection and cleaning 4. Titanium welding neck flange (used in petrochemical and pharmaceutical fields)

Titanium Grade 2 Flanges Specifications:

Titanium Grade 2 Flanges Picture:

Ti Flange Quality test: •Ultrasonic flaw detection Mechanical testing, such as stretch zone • Active material identification-PMI test • Hardness test •Chemical Analysis-Spectral Analysis We have a team of skilled professionals and experts who are working hard to provide high-quality flanges. By following well-defined manufacturing processes and quality standards, we are manufacturing the highest quality titanium flanges. From the selection of the material to the final shipment of the flange, our experts supervise the entire process to maintain the quality of the flange.

|