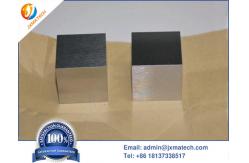

Machined 95WNiFe High Density Heavy Tungsten Alloy Cubes For

Counterweight

Heavy Tungsten Alloy Cubes has high density, high strength and high

hardness (commonly known as 3H alloy), and has good ductility,

conductivity and thermal conductivity. It plays an important role

in weapon manufacturing. Later, it is widely used in national

defense, aerospace and civil industry (such as electrical,

drilling, etc.). High gravity tungsten alloy materials have become

military and civil alloy materials.

SPECIFICATION & CHEMICAL COMPOSITION (NOMINALS)

| Chemical Composition | 90%W | 93%W | 95%W | 97%W |

| State | Sinter | Vacuum | Forge | Sinter | Vacuum | Forge | Sinter | Vacuum | Sinter | Vacuum |

Density

(g/cc) | 16.85-17.25 | 17.15-17.85 | 17.75-18.35 | 18.25- 18.85 |

Hardness

(HRC) | 32 Max | 30 Max | 40 Min | 33 Max | 31 Max | 40 Min | 34 Max | 32 Max | 35 Max | 33 Max |

| Tensile Strength (Max) | 770 Min | 900 Min | 1400

Max | 770 Min | 910 Min | 1440 Max | 735 Min | 920 Min | 700 Min | 850 Min |

Yield Strength

(Mpa) | 620 Min | 620 Min | 1280 Max | 650 Min | 650 Min | 1340 Max | 650 Min | 650 Min | - | - |

Elongation

(%) | 5 Min | 15 Min | 5 Min | 5 Min | 12 Min | 3 Min | 3 Min | 12 Min | 2 Min | 6 Min |

Heavy Tungsten Alloy Cubes Picture:

Introduction & Features of Tungsten Alloy Cubes

Tungsten alloy nuggets are mainly divided into two series, W-Ni-Fe

and W-Ni-Cu, and even w-ni-fe-cu. In contrast, W-Ni-Fe alloy has

better mechanical properties and plays a great role in various

departments of national defense industry and national economy. It

is a very important new military material in the national defense

industry, and gradually extends to various civil industries.

The content of tungsten in heavy tungsten alloy is between 90% and

98%, which is the reason for its high density (16.5-19.00 g / CC).

Nickel, iron and / or copper are used as metal binder substrates

for bonding. Fragile tungsten particles together make tungsten

alloys hard and easy to use. Nickel is the most commonly used

additive, including 7Ni: 3Fe or 8ni: 2Fe (by weight).

Application of Heavy Tungsten Alloy Cubes

Application of tungsten alloy

* Nuclear radiation protection screens, such as PET syringe

screens, vial screens, isotope containers, FDG containers,

multi-leaf collimators, etc.

*Balance weights, such as tungsten sinking bars, heavy metal boring

bars, ship crank camshafts, logging brackets, racing weights,

vibration reduction, dynamic balancing weights, etc.

*High voltage electrical contacts

*Electrodes for resistance welding