K20 K40 Tungsten Carbide Blades For Cutting Tools In Processing

Industry

The Tungsten Carbide Blades For Cutting Tools are made of

tungsten steel, which is an alloy material made of a hard compound

of refractory metal and bonding metal through powder metallurgy.

Tungsten steel has a series of excellent properties such as high

hardness, wear resistance, toughness, heat resistance and corrosion

resistance. Especially at 500°C, its high hardness and wear

resistance remain basically unchanged, and it still has a higher

hardness at 1000°C.

Tungsten carbide blades are mainly made of monolithic tungsten

steel and processed through a variety of production processes.

Tungsten carbide, also known as cemented carbide, is made of

high-quality tungsten carbide + cobalt powder through mixing,

pressing and sintering. It has high hardness, high strength, high

wear resistance and high elastic modulus. It belongs to the powder

metallurgy industry. As the teeth of modern industry, cemented

carbide tools play a fundamental role in promoting the development

of manufacturing.

According to the grain size, tungsten steel can be divided into

ordinary cemented carbide, fine-grained cemented carbide, sub-fine

and ultra-fine-grained cemented carbide, and newly introduced

double-crystal cemented carbide. According to its main chemical

composition, it can be divided into tungsten carbide-based cemented

carbide and titanium carbide-based cemented carbide. Cemented

carbide has high hardness (86~93HRA, equivalent to 69~81hrc),

second only to diamond, high thermal hardness (up to 900~1000℃,

maintained at 60HRC); high bending strength (mpa5100), good impact

toughness and high Corrosion resistance, chemical inertness and

other characteristics that ordinary alloy blades do not have.

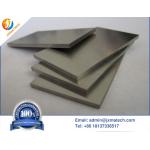

Tungsten Carbide Blades For Cutting Tools Picture:

How to keep Tungsten Carbide Blades For Cutting Tools

It is strictly forbidden to write or mark on the blade with an

electric pen or other scratching methods to prevent damage to the

knife body. The cutting edge of the foot cutter blade is extremely

sharp, but very brittle. In order to avoid injury to personnel or

accidental damage to the cutting edge, do not touch the cutting

edge to the human body or touch other metal hard objects. The

ready-to-use blades should be handed over to dedicated personnel

for safekeeping and storage, and must not be left alone to prevent

the blades from being damaged or causing accidents.