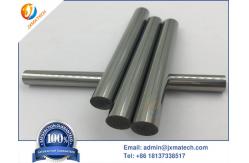

K10 K20 K30 Tungsten Carbide Rod With Good Wear And Bending

Resistance

Tungsten carbide rod is mainly made of WC tungsten carbide and

cobalt alloy powder by metallurgically mix, crush, ball mill,

press and sinter. The main components are WC and Co. Tunsten

carbide and Co contents in tungsten carbide rod for different

purposes are different and have a wide range of applications. In a

large range, cemented carbide has both good hardness and toughness,

so it has become the most widely applicable hard material and is

widely used in engineering and tool products.

Processing of tungsten carbide rod

- Cemented carbide may be damaged or deficient due to impact or

excessive processing load.

- During processing, please confirm that the product has been firmly

fixed on the installation platform without looseness before

operation.

- Cemented carbide is not impact resistant. Do not use metal hammer.

- Cemented carbide is not easy to be adsorbed on magnet. When using

magnet (magnet), please confirm that the product has been firmly

fixed before operation.

- The machined surface after grinding and grinding is extremely

smooth and the edges and corners are very sharp. Please pay full

attention when taking processed products.

Specifications Table of tungsten carbide rod

| WC bar / rod | Diameter | Length |

| Type | Size (mm) | Tolerance (mm) | Size (mm) | Tolerance (mm) |

| JX040-50 | 4 | +0.2~0.4 | 50 | 1 |

| JX050-50 | 5 | +0.2~0.4 | 50 | 1 |

| JX060-50 | 6 | +0.2~0.4 | 50 | 1 |

| JX060-60 | 6 | +0.2~0.4 | 60 | 1 |

| JX080-60 | 8 | +0.2~0.4 | 60 | 1 |

| JX100-75 | 10 | +0.2~0.4 | 75 | 1.5 |

| JX100-100 | 10 | +0.2~0.4 | 100 | 2 |

| JX120-75 | 12 | +0.2~0.4 | 75 | 1.5 |

| JX120-100 | 12 | +0.2~0.4 | 100 | 2 |

| JX140-100 | 14 | +0.3~0.5 | 100 | 2 |

| JX160-100 | 16 | +0.3~0.5 | 100 | 2 |

| JX200-100 | 20 | +0.3~0.5 | 100 | 2 |

Application of tungsten carbide rod

Tungsten carbide rod is mainly used to make various metal and

non-metal cutting tools, such as PCB micro drill, drill bit, end

mill, reamer, etc. it is used to process aluminum alloy, stainless

steel, heat-resistant alloy steel, nodular cast iron, nickel base

and titanium alloy, non-ferrous metal and other products. Tungsten

steel bars are also widely used in stamping tools and

wear-resistant tools, such as plug-ins of various shapes, silicon

steel sheets and cold-rolled plates, punches, thimbles and punching

needles of stainless steel.