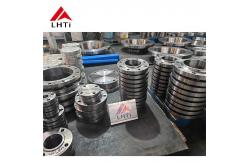

Titanium Flange Solutions Redefining Performance in Marine and Offshore Environments

|

|

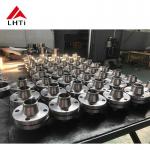

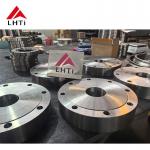

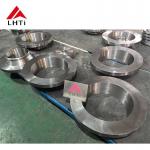

Innovative Titanium Flange Solutions for Marine and Offshore ApplicationsIntroductionIn the demanding environments of marine and offshore applications, the choice of materials is critical to ensure both safety and operational efficiency. Titanium has emerged as a leading material due to its outstanding strength-to-weight ratio, excellent corrosion resistance, and durability under extreme conditions. This article explores innovative titanium flange solutions tailored for marine and offshore applications, highlighting their advantages, design considerations, and future potential. Advantages of ASME B16.5 Titanium Blind FlangesASME B16.5 titanium blind flanges provide key benefits tailored for industrial applications:

The Significance of Titanium in Marine EnvironmentsMarine environments present unique challenges due to the combination of saltwater exposure, high humidity, and mechanical stress. Traditional materials like carbon steel and even stainless steel can succumb to corrosion, leading to structural failures and costly repairs. Titanium, on the other hand, exhibits remarkable resistance to seawater and various corrosive agents, making it an ideal candidate for applications in shipbuilding, offshore drilling rigs, and subsea equipment. The corrosion resistance of titanium stems from the formation of a stable oxide layer on its surface, which protects the underlying metal from aggressive environmental conditions. This characteristic significantly extends the lifespan of components, reducing maintenance frequency and costs over time. In marine applications, where equipment is often submerged or exposed to harsh elements, the durability of titanium flanges ensures the integrity of connections and minimizes the risk of leaks or failures. Advantages of Titanium FlangesTitanium flanges offer several advantages over conventional flange materials, making them a preferred choice for various marine and offshore applications. Firstly, the lightweight nature of titanium facilitates easier handling and installation, which is particularly beneficial in offshore environments where weight constraints are critical. The reduced weight can lead to significant savings in both transportation and installation costs, allowing for more efficient project execution. Another key advantage of titanium flanges is their high tensile strength, which enables them to withstand the demanding pressures and stresses typical of offshore operations. This strength translates to enhanced safety, as components are less likely to fail under load or impact. Furthermore, titanium flanges are resistant to galvanic corrosion, which can occur when dissimilar metals are in contact in a conductive environment. This property makes them an excellent choice for use with other marine materials, reducing the risk of electrochemical reactions that can compromise the integrity of the connections. Design Considerations for Titanium FlangesWhen designing titanium flanges for marine applications, several factors must be taken into account to ensure optimal performance. Flange design involves a careful balance of thickness, diameter, and bolt hole configuration, all of which must meet specific pressure and temperature requirements. Engineers must also consider the specific application environment, including potential exposure to corrosive substances and mechanical stresses. Additionally, the manufacturing process of titanium flanges requires precision and expertise. Titanium can be challenging to machine due to its hardness and propensity to work-harden, necessitating the use of specialized tools and techniques. Advanced manufacturing methods, such as CNC machining and water jet cutting, are often employed to achieve the required tolerances and surface finishes, ensuring that the flanges will perform reliably in high-pressure situations. The integration of industry standards and regulations is also a crucial aspect of flange design. Compliance with organizations such as the American Petroleum Institute (API) and the International Organization for Standardization (ISO) ensures that titanium flanges meet stringent safety and quality requirements. This adherence to standards not only enhances the credibility of the products but also fosters trust among users in marine and offshore sectors. Applications in Offshore Oil and GasIn the offshore oil and gas industry, the application of titanium flanges is particularly prominent due to the extreme conditions faced in drilling and production operations. Flanges are integral components of pipelines and valves, playing a vital role in ensuring secure and leak-free connections. Titanium’s superior corrosion resistance is especially beneficial in environments where saltwater and various hydrocarbons are present, as these conditions can rapidly degrade conventional materials. Moreover, the lightweight properties of titanium flanges contribute to the overall efficiency of offshore operations. As drilling rigs and platforms become increasingly sophisticated, the need for lightweight yet robust components has never been more critical. Titanium flanges facilitate the construction of streamlined systems that enhance operational efficiency while maintaining safety standards. Additionally, the use of titanium flanges can lead to significant long-term cost savings. While the initial investment in titanium components may be higher than that of traditional materials, the reduced maintenance needs and extended lifespan of titanium flanges often result in lower total lifecycle costs. This economic advantage is particularly appealing to companies operating in the competitive oil and gas sector, where cost efficiency is paramount. Marine Vessel ConstructionThe shipbuilding industry also benefits from the innovative use of titanium flanges. In the construction of marine vessels, weight savings are essential for enhancing fuel efficiency and improving performance. Titanium flanges, being significantly lighter than their steel counterparts, contribute to the overall reduction in weight of the vessel, enabling higher speeds and lower fuel consumption. In addition to weight savings, the corrosion resistance of titanium flanges is vital in prolonging the lifespan of marine vessels. Given that ships are continually exposed to seawater, the durability of titanium components helps prevent rust and deterioration, ensuring that vessels remain seaworthy for longer periods. This longevity reduces the frequency of repairs and overhauls, translating to cost savings for shipowners and operators. Furthermore, the application of titanium flanges aligns with the growing emphasis on sustainability in the maritime industry. As environmental regulations become stricter, the need for materials that enhance the lifespan of marine vessels while minimizing their environmental impact is increasingly critical. Titanium’s recyclability and long service life make it an attractive option for environmentally-conscious shipbuilders seeking to reduce their carbon footprint. Subsea ApplicationsSubsea applications present some of the most demanding conditions for flange systems, where pressures can reach hundreds of thousands of psi and temperatures can vary dramatically. Titanium flanges are uniquely suited for these environments due to their ability to withstand extreme pressures without compromising structural integrity. This capability is crucial in subsea pipelines and equipment, where even minor failures can have catastrophic consequences. The use of titanium in subsea applications also addresses the challenges of cathodic protection, a method used to prevent corrosion in submerged environments. Since titanium flanges are resistant to galvanic corrosion, they can be safely used with other metals in cathodic protection systems without risking degradation. This compatibility enhances the reliability of subsea installations, ensuring that all components work harmoniously to prevent corrosion and maintain safety. Moreover, as the demand for deepwater exploration continues to rise, the innovation surrounding titanium flanges is expected to evolve. Research and development initiatives focused on enhancing the performance of titanium alloys will likely yield new materials with even greater resistance to extreme conditions, paving the way for advancements in subsea technology. This evolution will ensure that titanium remains a key player in the future of offshore engineering. Maintenance and InspectionTo ensure the reliability and longevity of titanium flanges in marine and offshore applications, proper maintenance and inspection protocols are essential. Regular checks for signs of wear, corrosion, or fatigue can help identify potential issues before they lead to failures. The lightweight nature of titanium makes handling easier during maintenance activities, allowing for more frequent inspections without compromising safety. Non-destructive testing (NDT) methods, such as ultrasonic testing and eddy current testing, are often employed to assess the integrity of titanium flanges. These techniques enable operators to detect any anomalies without causing damage, ensuring that flanges remain in optimal condition. Additionally, the adoption of digital monitoring technologies can further enhance maintenance practices by providing real-time data on flange performance and condition. Effective maintenance not only extends the lifespan of titanium flanges but also enhances the overall safety of marine and offshore operations. By implementing a proactive maintenance strategy, operators can mitigate risks and ensure that their systems continue to function smoothly in challenging environments. This commitment to maintenance reflects a broader industry trend toward prioritizing safety and reliability in marine engineering. Future Trends and InnovationsLooking ahead, the future of titanium flange solutions in marine and offshore applications is bright, with ongoing innovations and advancements on the horizon. As material science continues to evolve, new titanium alloys are being developed that offer improved properties tailored for specific applications. These innovations may enhance the performance of titanium flanges even further, making them even more suitable for extreme marine conditions. Additionally, advancements in manufacturing technologies, such as additive manufacturing, hold promise for creating complex flange geometries that were previously difficult or impossible to achieve. This approach not only allows for greater design flexibility but also reduces waste in the manufacturing process, aligning with sustainability goals. As industries strive to minimize their environmental impact, the adoption of innovative manufacturing techniques will become increasingly important. Furthermore, the growing focus on automation and digitalization in marine and offshore sectors is expected to influence the development of titanium flange solutions. Smart sensors and IoT technologies can be integrated into flange systems to monitor conditions and provide valuable data for predictive maintenance. This integration will empower operators to make informed decisions, optimizing the performance and safety of their marine and offshore operations. ConclusionInnovative titanium flange solutions are revolutionizing marine and offshore applications by offering unparalleled advantages in corrosion resistance, lightweight construction, and durability. As industries continue to face the challenges of extreme environments, the use of titanium becomes increasingly vital in ensuring the safety and reliability of systems. With ongoing advancements in material science and manufacturing technologies, the future of titanium flanges holds great promise, paving the way for enhanced performance and sustainability in marine engineering.

Specifications for ASME B16.5 Class 150 Titanium Blind Flange

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Weld Neck Flanges ASME B16.5 RF MFM TG RJ FF Gr1 Gr2 Gr5 Baoji Customized |

|

Titanium Flanges Essential Components in the World of Biomedical Engineering | Titanium Flanges Connecting Bone |

|

Designing Titanium Flanges for High-Stress Oil and Gas Applications |

|

Titanium Flanges | Enhancing System Reliability with Titanium Flanges in High-Temperature Applications |

|

hexagon flange | flat flange | Corrosion-Resistant Titanium Flanges Enhancing Longevity in Chemical Processing |

|

ASME B16.5 and Titanium Flanges Types Design and Advantages According to the Standard |