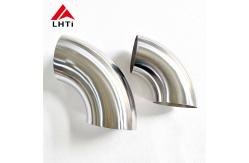

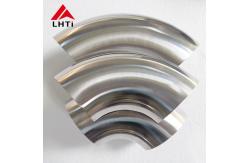

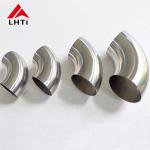

Seamless Gr2 Titanium Elbow / Bends With 1.2mm For Exhaust Parts

|

|

Gr2 Titanium Elbow / Bends With 1.2mm For Exhaust Parts

Our ASTM B363 UNS R50250 Titanium Buttweld Pipe Caps have some excellent features like toughness at extremely high temperatures, lightweight yet durable and as they possess a massive tensile strength. Titanium Buttweld DIN 3.7035 Seamless Fittings are basically used to the aerospace industry but, due to their numerous unique properties, are also used in chemical, medical and military applications, as well as in sporting goods. Thus our WNR 3.7165 Titanium Buttweld Pipe Elbow containing titanium are known for their high strength, lightweight, and exceptional corrosion resistance.

Product picture:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Seamless Titanium Pipe Bends Exhaust Parts Gr2 Titanium Elbow 1.2mm Titanium Bends | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Gr2 Gr7 Gr9 Short Radius And Long Radius Elbow 45 90 Degree ASME B16.9 |

|

Titanium Elbow with Polished Surface for Industrial Piping |

|

Grade 5 Titanium Elbow 90 LR Sch 40 ASME B16.5 ASTM B363 |

|

Gr2 titanium mandrel bends 90 degree elbow for exhaust pipe fittings |

|

titanium exhaust elbow 120 and 90 and 45 degree ASTM B363 pure titanium elbow use for car and motorcycle retrofit |

|

titanium bend/ elbow price Gr2/TA1 exhaust Titanium bends 45 Degree 90 Degree 180 Degree Titanium Elbow |