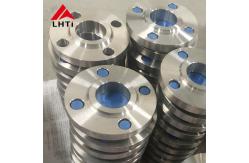

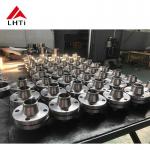

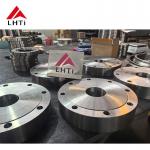

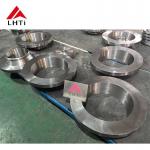

Welding Machining Titanium Flange Polished Surface Gr1 Gr2 Gr5 Gr7 Gr12

|

Detailed Product Description

Welding Machining Titanium Flange Polished SurfaceEnvironmental conditions: Understand the environmental conditions

of the pipeline system, including temperature, pressure, corrosion

properties of the medium, etc., to ensure the selection of

appropriate titanium alloy materials and flange types.

|

||||||||||||||||||||

| Product Tags: Welding Machining Titanium Flange Titanium Blind Flange Gr5 Polished Surface Titanium Pipe Flange |

Related Products

|

Weld Neck Flanges ASME B16.5 RF MFM TG RJ FF Gr1 Gr2 Gr5 Baoji Customized |

|

Titanium Flanges Essential Components in the World of Biomedical Engineering | Titanium Flanges Connecting Bone |

|

Designing Titanium Flanges for High-Stress Oil and Gas Applications |

|

Titanium Flanges | Enhancing System Reliability with Titanium Flanges in High-Temperature Applications |

|

hexagon flange | flat flange | Corrosion-Resistant Titanium Flanges Enhancing Longevity in Chemical Processing |

|

ASME B16.5 and Titanium Flanges Types Design and Advantages According to the Standard |

Email to this supplier