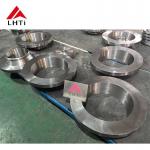

Material Grade: Gr1, Gr1, Gr2, Gr3, Gr4, Gr7, Gr9, Gr12

Standard: ANSI B16.5,JIS B2220, DIN2627-2628,ASME,GB/T 9116, ASTM B16.5.

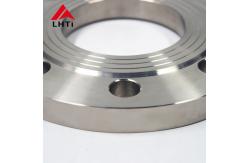

Technique: Forged and CNC Machined.

Type: WNRF , SORF , TH, BLIND ,SW, PL.

Application: used in cars, glasses,medical equipment , electronics ,

petrochemical equ ipment.

Advantage: Long service life, corrosion -resistant, hign yeiled strenth and

tensile strength.size | 1/2"~ 30"NB, NPS 1/2 - NPS 24 (DN 10 - 2000) | Pressure Class | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40,

PN64, etc/ | Flange Face Type | Flat Face(FF), Raised Face(RF), Ring Type Joint(RTJ) | Grade | Titanium Gr1, Titanium Gr2, Titanium Gr4, Titanium Gr5, Titanium

Gr7 | Available Dimensions | OD:200-1300mm ID:100-900mm Height:35-250mm |

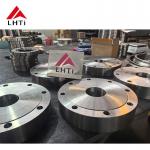

Related Products (Click on the image to enter the link) Plate Flat Welding Flange Titanium Gr 2 Flanges are widely used in various industries

including petrochemical, oil and gas, power generation, bulk liquid

transportation, chemicals, pharmaceuticals, pulp and paper

manufacturing, textiles and others. All our Ti Alloy Gr 2 Flange

are

manufactured in accordance with international standards. Titanium

Gr 2 Pipe Flange are packaged . Standard export packaging is

done in plywood cases, inside is filled in foam films to protect

goods to ensure that there is no damage during transit. All

Titanium Gr 2 Plate Flanges are marked with Grade, Lot No, Size,

Degree and our trade mark. On special requests we can also, make

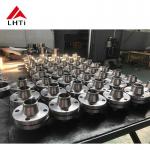

custom marking on Gr 2 Titanium Flanges. Production Flow Raw Material ⇒ Inspection Material ⇒ Cutting ⇒ Heating ⇒ Forging ⇒

Heat Treatment ⇒ Machining ⇒ Drilling ⇒ Marking ⇒ Washing/Cleaning ⇒ Final Inspection ⇒ Packing ⇒ Delivery 1. Service

* We have the stocks so we would provide our clients the short

delivery time

* Strict control from raw materials till products finished, so the

quality is guaranteed.

* Customized sizes are offered as well as specified sizes and

multiple sizes.

* Strict quality test from raw material to product.

* Original mill sheet test reports EN 10204.3.1 is available.

2. Quality Assurance

A. According to globally recognized standards, such as ASTM, AMS,

ASME. Provide third-party inspection reports. ISO Quality

Management System.

B. Visual inspection to check surface quality, ensuring without

flaw, black dot and other defects.

C. Chemical Composition making sure all chemical components can

satisfy customer’s demands.

D. Mechanical Property testing making sure all titanium products

have satisfying mechanical features before delivery.

Q1.--How can you ensure the product quality?

--All products are manufactured according to ASTM standard (Bolts

are according to ASME

standard and DIN standard),and we make 100% inspection before

shipment,also we can provide the

MTC Material Test Certification.

Q2.--Can you print our LOGO on the products?

--Sure, and we welcome the customized products.

Q3.--Can we get the free sample?

--Sure.

Q4.--What about the payment terms?

--T/T, L/C,Paypal,Western Union,Escrew and MoneyGram etc are all

accepted.

05.--What is the necessary information for a inquiry?

--Product name, specification, material grade and quantity. If

customized products, your drawing and

special requests also needed. |