Pickling Titanium Gr2 Seamless U Tube ASME SB338 For Heat Exchanger

|

|

Titanium Gr2 seamless U tube ASME SB338

Titanium U tubes are increasingly used in various occasions. A common titanium grinding product is titanium tube. Because of its superior corrosion resistance and strength weight ratio, titanium U tube is used in various products. The development of many different alloys has expanded the application of titanium in industry, chemical processing and power generation.

Precautions for titanium pipe processing:

Titanium strip coil—Slitting forming—Welding—Shaping and sizing—Heat treatment—Straightening—Eddy current and ultrasonic testing—Air tightness testing—Finished welded pipe During the deformation process, titanium pipe will gradually reduce wall and diameter with the rotation and feeding of the rolling mill. The pipe size required by the process can be obtained only after 5 ~ 10 rolling and finishing in one rolling pass. The cold rolling pipe mill can carry out large diameter reduction and wall reduction, but the dimensional accuracy is low after rolling, and the pipe end is prone to cracking, uneven concave convex and other phenomena. The cracking phenomenon can be solved mainly by grinding and leveling before pipe blank processing; For the uneven pipe end, similar to the "fish mouth" phenomenon, flat head treatment is required in the subsequent processing process, otherwise it will cause the plug stuffy accident. Therefore, this paper analyzes from the aspects of process, tooling and equipment, in order to find out the causes of uneven concave convex of pipe end and take effective measures to solve it. Detailed Information

Material: Gr1, Gr2 Standard: ASTM B338 Size: OD9.52mm/12.7mm/15.9mm/19mm/21.7mm/25.4mm/32mm/33.4mm/38mm/45mm etc., WT0.5-3.0mm , L Max 12000mm Wall thickness tolerance: +/- 10% Length tolerance: +3.2mm Type: Welded/Seamless Surface: Polishing, Pickling

Chemical composition (Wt%)

Physical Properties (Min)

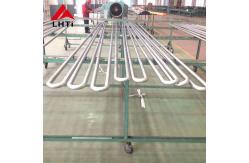

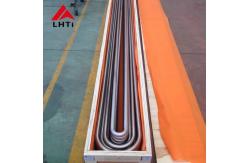

Detailed images:

U-tubes test : PMI +Penetrant testing Titanium tubes Quality inspections: UT ,PT ,Hydrodtatic test, Eddy current inspection,Chemical composition inspection,Dimention inspection, Tensile testing, Radiographic inspection,Thickness inspection,PMI inspection

Titanium pipes / titanium tubes used in heat exchanger:

About us

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Titanium Gr2 Seamless U Tube ASME SB338 Seamless U Tube Pickling Titanium U Tube | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Lightweight and Strong Titanium Tube for Structural Applications | grade 2 titanium tube |

|

Industrial Titanium Tube The Ultimate Combination of Strength and Durability |

|

Superior Titanium Tube for Industrial Exceptional Durability | welding titanium tubing |

|

High-Grade Titanium Tube for Superior Performance and Longevity |

|

Titanium Tube Lightweight and Corrosion-Resistant for Optimal Performance |

|

Lightweight and Strong Titanium Tube for Automotive Applications | reducing weight | titanium welded pipe |