Annealed Grade 5 Ti6Al4V Titanium Alloy Bar CNC Machined For Industry

|

|

Annealed Grade 5 titanium (Ti6Al4V) Titanium Alloy Bar

1. Product Information

Material: Gr5 titanium

Gr 5 titanium alloy bar / rod Chemical Composition

Gr 5 titanium bar / rod Mechanical Properties

Equivalent Grades for Gr 5

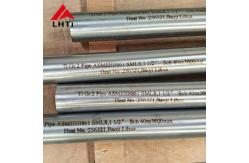

2.Detailed Images

3. Tolerance

4. package

6. Production Process

Titanium rod processing Flow:

Titanium Sponge and master alloys → Compacting electrodes → Melting → Forging → Billets → Procision forging → Machining → Bars

7. Quality Assurance:

A. According to globally recognized standards, such as ASTM, AMS, ASME. Provide third-party inspection reports. ISO Quality Management System.

B. Visual inspection to check surface quality, ensuring without flaw, black dot and other defects.

C. Chemical Composition making sure all chemical components can satisfy customer’s demands.

D. Mechanical Property testing making sure all titanium products have satisfying mechanical features before delivery.

8. FAQ

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: CNC Machined 6al4v Titanium Rod Annealed Titanium Alloy Bar Grade 5 Titanium Alloy Bar | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

welded titanium bar | Titanium Alloys Bar at GR1 GR2 GR5 and GR7 |

|

titanium welded bar| Maximize Efficiency with High-Performance Titanium Bar GR1 to GR7 |

|

ASTM B338 and B337 Standards for High-Performance Titanium Bars | small diameter titanium bars |

|

Manufacturing With Titanium Tube GR1 GR2 GR5 And GR7 | Titanium Alloy Tube | Titanium Welded Tube |

|

GR1 GR2 GR5 And GR7 Titanium Alloys The Optimal Solutions For High-Stress Conditions |

|

ASTM B338 and B337 Titanium Alloy Bars Essential for Marine and Industrial Applications |