High Frequency Welding Customized Coal Fired Steam Boiler Parts Stack Economizer Coil

|

|

High Frequency Welding Customized Coal Fired Steam Boiler Parts Stack Economizer Coil Boiler economizerBoiler Economizer is the energy improving device that helps to

reduce the cost of operation by saving the fuel. The economizer in

Boiler tends to make the system more energy efficient. In boilers,

economizers are generally designed to exchange heat with the fluid,

generally water. The exhaust from the boilers is generally in the

temperature range of 200°C – 250°C, so there are a huge amount of

losses from the boiler if any heat recovery devices are not

installed after it. Boiler Economizer that suit your boiler system

and will increase its overall efficiency from 3% – 5%. Increase in

boiler efficiency will save a lot of your operating cost and

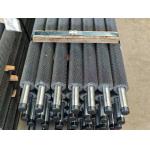

eventually will prolong the life of your boiler system. We can manufacture three types of boiler economizer, bare tube

economizer, H-finned tube economizer and spiral finned tube

economizer.

Product Description

1.Finned Tube Heat Exchangers consist of a shell and finned tubes assembly. 2.Fins are used to increase the effective surface area of heat exchanger tubing. 3.Finned tubes are used when the heat transfer coefficient on the outside of the tubes is appreciably lower than that on the inside;as in heat transfer from a liquid to a gas,vapor to a gas ,such as steam to air heat exchanger, thermic fluid to air heat exchanger, when an extended surface is needed on only one fluid side or when the operating pressure needs to be contained on one fluid side.

Technical parameter

Features

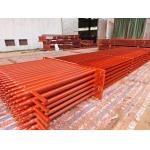

1. The equipment body can be designed into many modules to ensure the long term and stable running; 2. Compact structure which can enlarge the heat exchanging area in order to add the heat transfer area and less leakage 3. Improve the heat transfer efficiency 4. Structure arrangement: In line or staggered arrangement

Details

1.Our products can be modified according to our customers' needs

and the situation. 2.we design and manufacture safe,reliable and efficient H-fin

tubes.HD BOILER has also completed stand-alone product quality

assurance systems. 3.Production of H-fin tubes are with high heat transfer efficiency,

they have flue gas resistance and are designed for a small space.

Company Introduction Established in 1985,Zhangjiagang Hua Dong Boiler Co.,Ltd.(trading as HD Boiler),produces power plant; industrial; waste heat; waste incineration; biomass; organic heat carrier and electric steam boilers. Coupled with a comprehensive range of heating surfaces, HD Boiler brings to the market a unique service including boiler design , fabrication, installation, maintenance and replacement of boiler pressure parts.

1. Fabrication area of 200,000 square meters 2. 150 Engineers 3. 600 Coded welders 4. 60 Licensed Inspectors(NDT Level-III instructors) 5. Class-A Licenses for Design and Manufacture Boiler 6. ISO 9001:2008 Quality System 7. ASME Certificate of Power Boilers 8. ASME 'S','U' and NB stamp authorization

|

||||||||||

| Product Tags: High Frequency Welding Economizer Coil High Frequency Welding Stack Economizer Coil Customized Stack Economizer Coil |

|

Spiral Fin Tube Alloy Steel Carbon Steel Stainless Steel Heat Transfer |

|

Customizable Spiral Serrated Fin Tubes For Economizer Systems In Boilers |

|

Customizable ASME Fin Tubes For Durable Boiler |

|

ASME Spiral Fin Tube Stainless Steel Boiler Parts For Heat Dissipation |

|

Customized H Shaped Fin Tube For Efficient Boiler Heat Exchange |

|

Customized Economical Spiral Finned Tube For Enhanced Reliability |