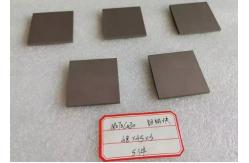

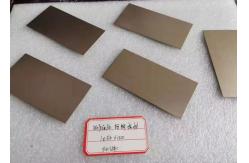

Mo80Cu20 Molybdenum Copper Alloy Plates Machined Parts Stamping Processing

|

|

Mo80Cu20 Molybdenum Copper Alloy Plates and Plate Machined Parts

Molybdenum Copper Alloy Discription Molybdenum copper alloy is used as heat sink material due to its high thermal conductivity. The properties of the two alloys are similar, and the density of molybdenum copper alloy is less than that of tungsten copper alloy. The preparation of molybdenum copper alloy mainly adopts the melt immersion method, using high-quality molybdenum powder and oxygen free copper powder, and applying isostatic pressing molding (high-temperature sintering copper infiltration), with fine structure, good arc breaking performance, good electrical conductivity, good thermal conductivity and small thermal expansion.

Molybdenum copper alloy is made of molybdenum and copper by powder metallurgy. There is little mutual solubility between molybdenum and copper. By adjusting the proportion of molybdenum and copper, the thermal expansion coefficient and thermal conductivity of molybdenum copper alloy can be controlled. The density of molybdenum copper is much smaller than that of tungsten copper, so it is more suitable for aerospace and other fields.

Applications of Molybdenum Copper Alloy Radiator microwave carrier Microelectronic packaging substrate and shell Ceramic carrier GaAs and silicon device base laser diode base surface mount encapsulated conductor microprocessor cover Electronic packaging materials for optical communication, microwave, RF and other fields.

Molybdenum Copper Alloys Properties:

We make all kinds of MoCu alloy products as request. We could offer Best Quality Customized Molybdenum Machined Parts Based Drawing

|

||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Molybdenum Copper Alloy Plates Mo 80 Cu 20 Molybdenum Copper Plate Stamping Processing Molybdenum Copper Plate |

|

ASTM B386 Molybdenum Plate Machined 200mm For High Temperature Vacuum |

|

Mo1 Cold Rolled Molybdenum Sheet With Thickness 0.05mm Mirror Surface |

|

99.95% Pure Molybdenum TZM / Alloy Bars With Dia 200mm |

|

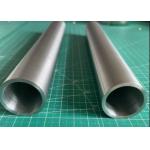

99.95% High Temperature Resist Molybdenum Tube 20 Mm For Thermocouple 2300°C |

|

Mo80Cu20 Molybdenum Copper Alloy Plates Machined Parts Stamping Processing |

|

MO1 Pure Molybdenum Rod Machined Parts Mo bar Vacuum Furnace Heating Chamber |