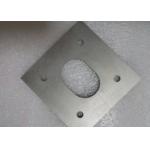

Molybdenum TZM Alloy Plate Components Applied As Functional Material

|

Molybdenum Alloy TZM Plate Components Applied As Functional MaterialDescription:TZM alloy is Titnaium-Zirconium-Molybdenum Alloy and it is one of commonly used high temperature molybdenum alloy. TZM alloy has good mechanical properties, especially at high temperature.

Physical performance comparison between TZM alloy and Pure Molybdenum

TZM (Ti0.5/Zr0.08) High temperature tensile strength and elongation

TZM (Ti0.5/Zr0.1)Thermal and electrical properties

TZM alloy (molybdenum zirconium titanium alloy) also has good welding performance and can be well welded with H11 steel and other materials. At the same time, TZM alloy can resist the corrosion of liquid metal such as Zn. It can be cold worked by conventional methods. In the case of cooling lubricating oil, can use emented carbide or high-speed steel tools to machine.

Parameters

TZM molybdenum alloy can be applied for jet tube of flying vehicle and a variety of components of high temperature, high pressure turbine engine, such as hot gas seals and valves, turbine wheels or wheel blades.

We also can make TZM customized parts according to drawings.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Molybdenum TZM Alloy Components Functional Material TZM Alloy Molybdenum Alloy Functional Material | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Bright Surface Molybdenum Sheet TZM MoLa Alloy For High Temperature Vacuum Furnace |

|

High Strength TZM Molybdenum Alloy Bars With HRC18 - 20 |

|

Titanium Zirconium Molybdenum Plate TZM Alloy Machined Parts Ground Bright |

|

99.95% Molybdenum TZM Alloy Plate Processed Parts Final Machined Surface |

|

Pure molybdenum molybdenum alloy TZM/MoLa Sheet for Vacuum Furnace |

|

TiZrMo Molybdenum TZM Alloy Plate Shaped Parts Vacuum Furnace |