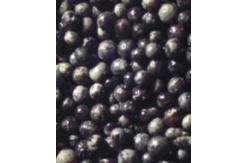

0.053mm~2.50mm Ceramic Foundry Sand Good Flowability And Heat Conductivity

|

|

Ceramic Foundry Sand WithGood Flowability And Heat Conductivity

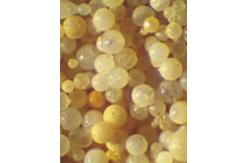

1.GOLDEN SAND FOR 3D PRINTING Mining Machine Spare Parts Golden Sand,a newly developed special artificial sand especially to meet the demand for 3D printing sand molds and cores, has a golden, brilliant appearance and good spherical shape. Those 3D printing company who uses this kind of sand, may take the advantages,such as: reduced resin(binder)consumption,high strength, fast curing and excellent sand mold(core or shell)surface quality. Golden sand will be the best choice for sand mold 3D printing.

2.Why Ceramic Sand Mining Machine Spare Parts 1) Prevention of sand expansion defects, especially finning/veining 2) Elimination of gas-forming additives 3) Prevention of reactions between metal and moulding sand 4. Prevention of metal penetration 5) Reduction of core weight 6) Improved flowability of moulding sand 7) Influence on the formation of microstructure 8) Pouring of thin-walled castings

3.Parts of papticle size distribution Mining Machine Spare Parts

4. Pimary Customers Abroad (Mining Machine Spare Parts)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Ceramic Foundry Sand Good Flowability 2.50mm Ceramic Foundry Sand 0.053mm ceramic foundry sand | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

CITIC IC Raymod Mill Small Crown Pinion Gear Mining Machine Spare Parts |

|

High Level Rotary Kiln Support Roller Ball Mill With High Precision |

|

High Chrome Ball Mill Casting And Forging Steel Balls 20-150mm |

|

high chrome ball mill casting and forging steel balls factory price and ball mill balls manufacturer |

|

Multi Layer Surfaces Grinding Welding Roller Of Mining Machine Spare Parts |

|

Customized High Quality High Manganese Steel Alloy Crusher Hammer Head For Mines |