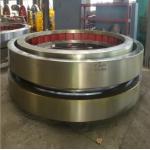

Castings And Forgings 45 # Steel Head Sheave For Mining Hoist

|

|

45 # Steel Head Sheave For Mining Hoist Castings And Forgings

1. Product features of Head sheaves castings and forgings In order to prolong the service life of the wire rope, the wheel rim is equipped with wear-resistant and pressure-resistant wedge liner, using D660 (or nylon 1010) liner.

(1) Eccentric arrangement: there is a disassembly and assembly space for replacing the bearing bush on one side of the swimming wheel, and only the maintenance and replacement of the bearing bush can be carried out without disassembling the whole sheet-wheel device.

(2) symmetrical arrangement: the four wheels are symmetrical relative to the two sides of the bearing seat, but the need to replace the bearing bush, can only be removed from the whole sheaf device.

2. Product parameters of sheet-wheel castings and forgings

3. Common faults and techniques of Head sheaves and guide wheels castings and forgings (1) For the burning tile problem of old structure Head head sheave sliding bearing, the lubrication mode should be improved; Because the crown wheel is installed on the derrick, it is inconvenient for daily maintenance, temperature alarm signal device should be added to timely maintain and prevent burning tile accident, or replace the original sliding bearing with rolling bearing structure. (2) For the old structure of the pulley without padding in the rope groove, no padding can be added on the original rope groove, so it is necessary to replace the pulley with padding, and the adjacent assembly size can be kept unchanged to facilitate installation; (3) For the mines with difficult transportation in mountainous areas or underground roadways, the crown wheel (guide wheel) can be replaced with a two-half structure or four-half structure.

FQA Q: Why we believe in luoyang zhongtai industries co., ltd: A: 1. More than 30 years experience. 2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts. 3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time : A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms : A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping.

|

||||||||||||||||||

| Product Tags: Head Sheave Castings And Forgings Mining Hoist Castings And Forgings |

|

Wear-Resistant Alloy Lining Plate Can Be Customized For Crusher And Ball Mill |

|

Long-Life Steel Balls With Good Toughness, Impact Resistance And Wear Resistance |

|

Customized Wear-Resistant High Chromium Alloy Lining For Ball Mill |

|

Rotary Kiln tyre For Enhancing The Rigidity Of The Cylinder |

|

Cost Effective High Quality And Customizable Steel Bolts |

|

High Temperature Resistant Slag Pot Casting Ladle Slag Transfer Container |