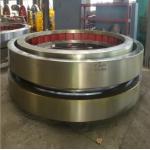

Rotary Kiln Large Wheel Tyre Castings And Forgings For Mining Equipment

|

|

Rotary Kiln Large Wheel Tyre Castings And Forgings For Mining Equipment

1. Product introduction of rotary kiln wheel belt Castings And Forgings Rotary kiln wheel Tyre also known as rotary kiln ring. The weight

of all parts of the rotary kiln, such as barrel, kiln lining and

materials, is transmitted to the supporting device through the

wheel Tyre. Luo Mine can specialized in the production of CITIC Heavy Industry rotary kiln, Luo Mine rotary kiln, including cement rotary kiln, lime rotary kiln, metallurgical rotary kiln, chemical rotary kiln and other rotary kiln. The rotary kiln Tyre (ring) made by our factory is made of ZG35CrMo or 42CrMo steel with excellent quality.

2. Castings And Forgings Cases of rotary kiln wheel belt products Made the world's largest cement kiln wheel Tyre Korea has become the third country in the world following France and South Korea to master the manufacturing technology of such components On the morning of February 8, 2007, the "wheel Tyre King" of cement kiln with output of ten thousand tons was 6.75 meters in diameter, 0.69 meters in wall thickness and 191 tons in weight. On the morning of September 3, 2007, 351 tons of molten steel was successfully cast into smister Cement kiln wheel Tyre. The diameter of the wheel Tyre was 8.421 meters, and the single weight of the blank was 194.2 tons. "Wheel king" is the core component of three super large cement kiln production lines with a daily output of ten thousand tons made by CITIC Heavy Machinery for Saudi Arabia Cement Company. Previously, Saudi Arabia originally planned to use European and American products, but after commissioning a Swiss company to conduct a comprehensive investigation of Citic Heavy Machinery Company, it firmly decided to choose "Made in China".

3.Castings And Forgings Rotary kiln wheel Tyre parameters:

FQA Q: Why we believe in luoyang zhongtai industries co., ltd: A: 1. More than 30 years experience. 2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts. 3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time : A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms : A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty? A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service? A: We can supply technical guide for machines running test and parts maintenance if end user needs.

After-sales service LUOYANG ZHONGTAI INDUSTRIES able to provide: 1. ENGINEERED SPARES - DESIGN AND MANUFACTURING 2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES 3. HUGE MACHINE SHOP CAPABILITIES 4. TRAINING PROGRAMMES 5. PREVENTATIVE MAINTENANCE PROGRAMS 6. PREVETATIVE MAINTENANCE SERVICES 7. COMPREHENSIVE MAINTENANCE PROGRAMS

LUOYANG ZHONGTAI INDUSTRIES’s Field Service Engineers are trained specifically in the LUOYANG ZHONGTAI INDUSTRIES brand group products but are capable of undertaking the servicing of other OEM brands. Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time. LUOYANG ZHONGTAI INDUSTRIES also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs.

|

|||||||

| Product Tags: Large Rotary Kiln Tyre Mining Equipment Rotary Kiln Tyre Castings And Forgings Kiln Tyre |

|

Wear-Resistant Alloy Lining Plate Can Be Customized For Crusher And Ball Mill |

|

Long-Life Steel Balls With Good Toughness, Impact Resistance And Wear Resistance |

|

Customized Wear-Resistant High Chromium Alloy Lining For Ball Mill |

|

Rotary Kiln tyre For Enhancing The Rigidity Of The Cylinder |

|

Cost Effective High Quality And Customizable Steel Bolts |

|

High Temperature Resistant Slag Pot Casting Ladle Slag Transfer Container |