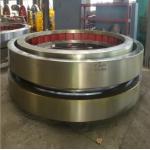

Customized Castings And Forgings Thrust Roller And Wheel Steel

|

|

Customized Castings And Forgings Of Thrust Roller Wheel Steel Wheel

1. Product description of thrust roller wheel Castings And Forgings Hydraulic retaining wheel is used to control the axial movement of the rotary kiln body, so that the wheel belt and supporting wheel can be evenly worn on the full width, but also to ensure the straightness of the center line of the kiln body, so that the size of the gear meshing well, reduce power consumption.

2. Fault protection measures for thrust roller wheel Castings And Forgings In order to avoid similar problems in the future, we have taken corresponding protection measures based on the above analysis: (1) Improve the existing unreasonable structure or hidden parts; (2) Strict equipment management, improve and refine feasible operation specifications for the implementation of various projects; (3) In the field maintenance, the management department should strictly quantify the installation technical requirements and indicators, and the construction unit should make detailed arrangements for the feasibility of the operation plan according to the requirements; (4) Ensure that all common inspection data meet the requirements and specifications; (5) Ensure key quality control points such as interference of shaft hole fit, comprehensive mechanical properties of shaft and surface hardness of wheel disc; (6) Control whether each bolt reaches the required strength grade index, sealing ring performance is up to standard and other details; (7) Strengthen the technical training for workers, do a good job in daily spot inspection and maintenance, and report any problems in time.

3. Analysis of the reasons for the failure of thrust roller wheel Castings And Forgings Although there is no big fault in the hydraulic system, poor treatment may also cause kiln shutdown and production reduction.

(1) The interference of the shaft hole of the retaining wheel is small The baffle wheel and the shaft use a flat key interference connection, in order to prevent the baffle wheel axial channeling, the upper part of six anti-loosening bolts; The matching tolerance of the retaining wheel and solid shaft is selected according to the load transferred by the retaining wheel; According to the calculation of retaining wheel shaft hole matching theory selection; Once the actual interference is less than this value, the pressure on the mating surface will be too small to meet the working conditions under this working condition, resulting in relative sliding between the shaft holes, and the torsion force will act directly on the key, so that the torque transferred by the interference fit of the shaft hole will be changed into the torque transferred together with the key. Under impact load, especially when the key is also selected relatively loose fit can not meet the requirements of use, it is easy to cause rolling key, block wheel and other fault phenomenon.

(2) Axis class itself Shaft parts once improper material selection, may lead to its own mechanical properties can not meet the requirements of use; Improper processing or heat treatment may lead to stress concentration or crack source, which can easily lead to cracking failure. Rapid heating and cooling during welding repair will change the toughness of the matrix, and if the residual stress can not be eliminated well, it is easy to cause crack failure.

4. Parameters of thrust roller wheel Castings And Forgings

|

||||||||||||||||||||

| Product Tags: Customized Castings And Forgings Forgings Thrust Roller Wheel Castings Thrust Roller Wheel |

|

Wear-Resistant Alloy Lining Plate Can Be Customized For Crusher And Ball Mill |

|

Long-Life Steel Balls With Good Toughness, Impact Resistance And Wear Resistance |

|

Customized Wear-Resistant High Chromium Alloy Lining For Ball Mill |

|

Rotary Kiln tyre For Enhancing The Rigidity Of The Cylinder |

|

Cost Effective High Quality And Customizable Steel Bolts |

|

High Temperature Resistant Slag Pot Casting Ladle Slag Transfer Container |