Depth Indicator Mining Machine Spare Parts For Mining Machine

|

|

Mining Machine Spare Parts And Depth Indicator For Mining Machine

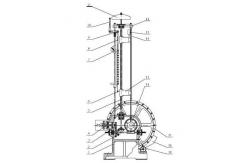

1. Product description of hoist depth indicator The single-rope archway depth indicator is composed of two parts, one is a device that transmits motion at right angles to the end of the main shaft of the hoist, that is, the archway depth indicator transmission device, and the other part is a depth indicator, which is connected by a coupling. The single-rope archway depth indicator is composed of two parts, one is a device that transmits motion at right angles to the end of the main shaft of the hoist, that is, the archway depth indicator transmission device, and the other part is a depth indicator, which is connected by a coupling. The depth indicator is equipped with archway type depth indicator, small lead screw type thick pointer indicator, round disk type fine needle indicator. Archway depth indicator also added a broken shaft protection device (depth indicator drive failure protection). Mining Machine Spare Parts And Depth Indicator For Mining Machine

2. Working principle of hoist depth indicator: The rotary movement of the main shaft of the hoist is transmitted to the depth indicator by the transmission device, and the screw is transmitted to the lead screw by the gear pair, so that the two vertical lead screws rotate in opposite directions to each other. As the lead screw rotates, the two trapezoidal nuts with Pointers also move in opposite directions, one up and the other down. The number of revolutions of the lead screw is proportional to the number of revolutions of the main shaft, and therefore corresponds to the position of the container in the wellbore. Therefore, the position of the pointer on the nut on the lead screw also corresponds to it, and the position of the container in the wellbore can be accurately indicated by the pointer. On the trapezoidal nut not only equipped with a pointer, and equipped with a pawl and touch the iron, as ascension container close to the wellhead uninstall the location, the pawl driven signal pin on the pull rod, would tie up gradually, the signals at the same time the pin in the horizontal direction in the mobile, when reach the deceleration point pin from the pawl whereabouts, in a signal the firing pin on the pull rod knock bell, signal slow start, A limit switch is fixed on the column next to the signal pull rod. When the lifting container reaches a certain position, the touch block on the signal pull rod will decelerate the roller of the reducer switch until it stops. If the hoist has been coiling, the iron touch on the trapezoidal nut will open the coiling limit switch for safety braking.

The pin on the signal pull rod can be moved according to the need, and the upper and lower positions of the deceleration limit switch and over winch limit switch can be easily adjusted to meet the requirements of different deceleration distance and over winch distance. Speed limiting CAM driven by the turbine, speed limiting protection through speed limiting rheostat or self-tuning machine, so that the hoist will not overspeed in the deceleration stage. The Angle of each CAM in a lifting process should be within 270 degrees ----330 degrees. Mining Machine Spare Parts And Depth Indicator For Mining Machine

3. Technical parameters of hoist depth indicator

|

||||||||||||||||||||||

| Product Tags: Depth Indicator Mining Machine Spare Parts Depth Indicator For Mining Machine Mine hoist depth indicator | ||||||||||||||||||||||

|

High Level Rotary Kiln Support Roller Ball Mill With High Precision |

|

High Chrome Ball Mill Casting And Forging Steel Balls 20-150mm |

|

CITIC IC Raymod Mill Small Crown Pinion Gear Mining Machine Spare Parts |

|

high chrome ball mill casting and forging steel balls factory price and ball mill balls manufacturer |

|

Multi Layer Surfaces Grinding Welding Roller Of Mining Machine Spare Parts |

|

Customized High Quality High Manganese Steel Alloy Crusher Hammer Head For Mines |