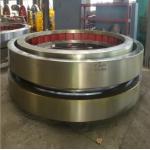

Customizable Castings And Forgings Semi Autogenous Mill Liner Long Service Life

|

|

Long Service Life, Customizable Semi-Autogenous Mill Liner Castings And Forgings

1. Semi-autogenous mill liner castings and forgings product description Zhongshi Heavy Machinery Company can specialized in the production of CITIC Heavy Industry semi-autogenous mill lining plate, luokang semi-autogenous mill lining plate. And can be customized to other models of brand semi-self mill lining board. Its strong casting and forging, heat treatment and machining capacity, strict quality and process control methods, perfect testing and experimental means, so that its production and development of all kinds of wear-resistant products enjoy a high reputation in China, and exported to overseas.

2. Product parameters of semi-autogenous mill liner castings and forgings (1) Optimize the structure and size of the lining plate by using internationally recognized advanced mill liner simulation special software. (2) The lining plate material of cylinder body and end cover is made of wear-resisting chromium-molybdenum alloy steel, and convex lining plate is adopted to improve service life and grinding effect. (3) The lining plate shall be fastened with flat head bolts, supporting self-locking nuts and sealing gaskets. The joint bolts have special sealing measures to prevent leakage. (4) The number of bolts to fix the lining plate is 5%. (5) Wear-resistant rubber filling strip is adopted at the joint of end cover liner and barrel, which is fixed by the adjacent liner. (6) The rubber liner between the cylinder body and the lining plate, the thickness is 6mm, can reduce the noise.

3. Ball mill liner castings and forgings product parameters

4. FQA Q: Why we believe in luoyang zhongtai industries co., ltd: A: 1. More than 30 years experience. 2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts. 3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time : A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms : A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty? A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service? A: we can supply technical guide for machines running test and parts maintenance if end user needs.

|

||||||||||||||||||||

| Product Tags: Customizable Semi Autogenous Mill Liner Forgings Semi Autogenous Mill Liner Castings Semi Autogenous Mill Liner |

|

Wear-Resistant Alloy Lining Plate Can Be Customized For Crusher And Ball Mill |

|

Long-Life Steel Balls With Good Toughness, Impact Resistance And Wear Resistance |

|

Customized Wear-Resistant High Chromium Alloy Lining For Ball Mill |

|

Rotary Kiln tyre For Enhancing The Rigidity Of The Cylinder |

|

Cost Effective High Quality And Customizable Steel Bolts |

|

High Temperature Resistant Slag Pot Casting Ladle Slag Transfer Container |