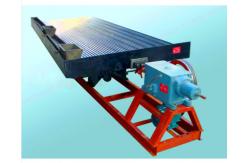

Ore Dressing Shaking Table For Gold Tin Coltan Tungsten

|

|

Ore Dressing Equipment Shaking Table For Gold Tin Coltan Tungsten

1. Scope of application of ore dressing equipment shaking table The dressing equipment is mainly used for sorting in 2-0.02 mm ore and slime level of tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold and other non-ferrous, black rare metal minerals, sorting 4-0.02 mm pyrite; After changing the form of bed strip appropriately, the final coal and slime are selected; And separate other mixed materials with sufficient specific gravity difference and suitable particle size composition.

2. Working principle of ore dressing equipment shaking table: Beneficiation process is conducted in with a copy of the tilting table surface, mineral grain group from the Angle of feeder trough into bed surface, and at the same time by lateral flushing water supply for the sink, ore grain in gravity, lateral flow momentum, asymmetry of bed surface for reciprocating motion under the action of the inertia and friction, according to the proportion and granularity theory, then make the longitudinal motion along the bed surface and lateral movement along the inclined bed surface. Therefore, the specific gravity and particle size of different ore particles along their respective movement direction gradually from side A to side B fan-shaped flow, respectively from the concentrate end and tailings side of different areas discharged, and finally divided into concentrates, middling and tailings.

3. Structural characteristics of ore dressing equipment shaking table: The dressing equipment is mainly composed of the head of a bed, motor, slope adjuster, bed surface, ore tank, water tank, strip and lubrication system and other eight system parts. The separation mechanism is the use of the specific gravity difference of the sorted minerals, the differential movement provided by the head of the bed, inclined water flow and different forms of the bed, so that the ore particles in the bed surface loose stratification, selective transport, the formation of fan-shaped zone on the bed surface, so as to produce different rich and poor products.

4. Product parameters of ore dressing equipment shaking table:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Ore Dressing Shaking Table Shaking Table For Gold Tin Shaking Table For Tin Coltan |

|

Magnetic Separators For The Wood Industry Mining Ceramics And Chemical Industry |

|

GPY Series Disc Filter With Compact Structure And New Star-Point Plastic Sector Plates |

|

Compact Structure And Reliable Operation GPY Series Disc Filter |

|

High Efficiency Energy Saving Iron Ore Metal Recovery Magnetic Separator |

|

Metallic Ore Dressing Agent / Gold Leaching Agent Environmental Protection |

|

4KW Ore Dressing Equipment Vacuum Disk Filter For Mining Metallurgy Chemical Industry |