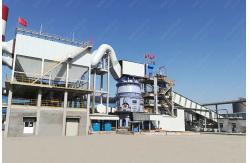

Mine Mill Steel Slag Vertical Mill Nickel Slag Ore Grinding Mill

|

|

Ore Grinding Mill Mine Mill Steel Slag Vertical Mill Nickel Slag Vertical Mill

1. Concept of Steel slag vertical mill Steel slag vertical mill integrating crushing, conveying, grinding, drying as one, new environmental protection and high efficiency, is the most ideal steel slag powder production equipment at present. The grinding efficiency of steel slag vertical mill is high, the power consumption of the system is less than 50kWh/t, the specific surface area of steel slag powder can reach 4500-5000 cm2/g, and the performance is superior.

2. Ore Grinding Mill Mine Mill Steel Slag Vertical Mill Nickel Slag Vertical Mill Suitable for enterprises: Cement plant, grinding station, steel plant, etc.

3. The working principle of Steel slag mill nickel slag vertical mill Material feeding tube falls into the center of the grinding disc, the constant speed rotating grinding disc with centrifugal force to evenly disperse and smooth the raw material outward, so that it forms a certain thickness of the material bed, the material at the same time by a number of grinding roller on the grinding disc, and was crushed. Under the continuous drive of centrifugal force, the material keeps moving to the outer edge of the disc. The material leaving the disc meets the hot gas entering the mill through the wind ring and rises accordingly, and enters into the separator through the middle shell of the mill. In this process, the material and the hot gas are fully heat exchange, and the water is quickly evaporated. The separator controls the fineness of the finished product at the exit of the roller mill. The particles larger than the specified size are separated and fall back to the grinding plate. The materials that meet the fineness requirements enter the finished product through the separator

4. Output: 200,000 to 1.3 million tons per year

5. Specific surface area: 4500~5000 cm²/g

6. System power consumption: ≤50 kWh/t

7. Product parametersof Ore Grinding Mill Product specification of Steel slag mill nickel slag vertical mill

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 4000mm Nickel Slag Vertical Mill Cement Plant Steel Slag Vertical Mill IOS Approved Nickel Slag Grinding Mill |

|

Raw Material Vertical Mill With Strong Drying Capacity And Low Metal Pollution |

|

Economic Environmentally Friendly And Yield-Increasing Mineral Processing Ball Mill |

|

Slag Grinding Production Line With Annual Output Of 1.2 To 3 Million Tons |

|

Grate Type And Overflow Type Ball Mills Advanced Steel Ball Grinding For Ore Grinding Mill |

|

Dry Or Wet Grinding Ball Mills For Mineral Processing Building Materials |

|

Metallurgy Industry Coal Stone Ball Mill Customizable For Various Coal Hardness |