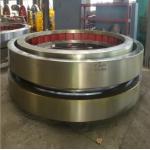

Heat Resistance HRC58 Castings And Forgings High Abrasion Resistance Grinding Table

|

|

good impact-resistance heat-resistance high abrasion resistance grinding table

Wear parts such as tires, grinding ring segments, armor rings and spindle shields are made from our wear resistant welding material ,and treated for optimum mechanical properties. Tires and grinding ring segments are also accurately machined to tight tolerances for precise fit. Parts requiring drilled or tapped holes such as roller bosses, clamping rings and dam ring segments are made of carbon steel or high strength steel. They are treated to provide the best combination of hardness and toughness for long, trouble-free service.

Composite wear-resistant steel plate radiating range is very wide, it can used in any equipment where the most serious wearing place in cement, glass, power, steel, chemical and other industries.Hard plate wear –resistance division manufactured composite wear-resistant steel plate, surfacing on a deposited layer of certain thickness wear-resistant alloy, hardness reaches to HRC58-62 which makes the plate wear-resistant and service life over 16Mn steel plate more than 14.6 times, at the same time with a good impact-resistance, heat-resistance, high abrasion resistance and other advantages. |

||||||||||||||||

| Product Tags: HRC58 Castings And Forgings Heat Resistance downdraft grinding table HRC58 downdraft grinding table |

|

Mining Machine Castings And Forgings Of Table Of Vertical Mill Accessories |

|

Wear-Resistant Alloy Lining Plate Can Be Customized For Crusher And Ball Mill |

|

Long-Life Steel Balls With Good Toughness, Impact Resistance And Wear Resistance |

|

Customized Wear-Resistant High Chromium Alloy Lining For Ball Mill |

|

Rotary Kiln tyre For Enhancing The Rigidity Of The Cylinder |

|

Cost Effective High Quality And Customizable Steel Bolts |