Efficiency Feeding 30mm Vertical Plastic 60TPH Sand Making Machine

|

|

efficiency widely used ZXS series vertical plastic sand making machine

Overview

ZXS series vertical plastic sand making machine is my company to develop a new kind of sand production equipment, the equipment on the basis of the original similar equipment to analyze practical path for the material, and according to the principle of the equipment material crushing targeted the overall module design, the stone hit stone and stone while the iron is hot, the principle of clever union, in order to increase the efficiency of crushing, its performance in all kinds of ores and finely equipment plays an irreplaceable role.

Scope of application

ZXS series vertical plastic sand making machine is widely used in various metal and non-metal ores, refractory materials, glass raw materials, cement, abrasive, building aggregate, artificial sand making and various metallurgical slag grinding operations. Especially for river pebbles, silicon carbide, emery, sintered bauxite, magnesia and other medium hard or abrasive materials, higher than other types of crusher production efficiency, in the mechanism of sand, its crushing and shaping ability and similar products have more advantages, is the most ideal shaping sand equipment.

Structural features

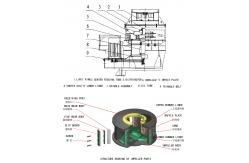

Working principle

ZXS series vertical plastic sand making machine adopts advanced selective crushing and desorbing crushing principle to directly apply enough kinetic energy to the material, and convert the kinetic energy to overcome the crushing energy required by the material through impact to crush the material. The material basically breaks along its natural grain surface and cleavage surface with good grain shape and low self consumption.

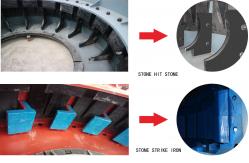

This machine can realize the conversion of two working principles of "stone beating" and "stone beating". "Stone hit stone" is to use the waterfall flow material systems, incoming material according to certain amount of controllable shunt into two road, all the material from the center into the feeding tube into the horizontal high-speed rotating impeller, the material all the way from the feed hopper circumferential multiple overflow mouth cavity in free fall equipment, into the lumen of the material by high-speed rotating impeller impeller speed from three or more mouth out, and the material is falling from the overflow mouth in the crushing cavity formed by the strong impact since the stone hit stone broken. "Stone-iron" is to introduce the material from the center of the feeding tube into the impeller of high speed rotation, and after accelerating, throw out from three or more launch ports to violently hit the metal counterattack plate installed in the inner wall of the crushing chamber of the equipment to form the crushing of stone-iron.

Technical parameters

Particle size distribution curve

Product advantage

1. Simple structure, easy installation and low cost;

2. Unique rotor and cavity design, large handling capacity and high sand forming rate;

3. Good grain shape and cube shape, good flow performance of the finished product;

4. Stable operation, low noise, high efficiency and energy saving;

5. In the production process, the material is lined with self-protection to reduce the wear of the casing;

6. Increase the design of vortex cavity to store a large amount of material in the cavity, greatly saving the loss of vulnerable parts;

7. Unique design of lining plate inside the vortex cavity, which greatly saves the use cost;

8. Dual-use machine, according to the industrial and mining can quickly achieve "stone", "stone" crushing two forms;

9. The product can be divided into two types, grease lubrication and thin oil lubrication, for users to choose;

10. Thin oil lubrication has good heat dissipation and sufficient lubrication, which is more advantageous than grease lubrication;

11. Automatic control system with current overload, excessive oil temperature, excessive vibration and other protection functions (this is optional for users).

Field case

|

|||||||||||||||||||||||||||||||||||

| Product Tags: 60TPH Sand Making Machine Feeding 30mm Sand Making Machine 60TPH 30mm plaster sand making machine | |||||||||||||||||||||||||||||||||||

|

Raw Material Vertical Mill With Strong Drying Capacity And Low Metal Pollution |

|

Economic Environmentally Friendly And Yield-Increasing Mineral Processing Ball Mill |

|

Slag Grinding Production Line With Annual Output Of 1.2 To 3 Million Tons |

|

Grate Type And Overflow Type Ball Mills Advanced Steel Ball Grinding For Ore Grinding Mill |

|

Dry Or Wet Grinding Ball Mills For Mineral Processing Building Materials |

|

Metallurgy Industry Coal Stone Ball Mill Customizable For Various Coal Hardness |