GS42CrMo4 Mill Girth Gear and rotary kiln gear for cement plant

|

|

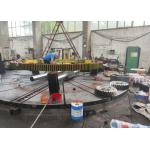

Product Description Girth Gears: Rotary kiln Girth Gear,ball mill Girth Gear

Girth Gears offered find extensive application in different industry sectors

including in sponge iron plants, steel & cement industry,

mining industry, wind mills as well as in other industry sectors.

These are made available in module range of 10 Module to 70 Module

and in minimum diameters of 100 mm to 15000 mm. Further, these

comprise maximum weight of 70 MT single pieces. Here the range of

hardened & ground gear boxes/gears comprise Worm gear boxes,

Helical / Double helical gears/gearboxes, Helical-Bevel gearboxes,

Planetary Gearboxes and others.

Module Range: 10 Module to 70 Module. Diameter : Min 100 mm to16000 mm. Weight : Max 120 MT single piece. Hardened & Ground Gear Boxes/Gears:

Ratings:

Send Enquiry With more than 1000 girth gears sold over the world CITICIC Gear is

a leading supplier in the cement and mineral industry. And as

member of AGMA (American Gear Manufacturers Association), we do

actively take part in defining the standard for gear rating

calculations and service factors. We provide girth gears in three different designs

Fabricated gears became more common in the past and are constructed with forged steel gear rim materials and electro welded body structure. The rings are manufactured from a whole block of high resistance alloy steel. After the rough machining of the ring, we carry out hardening and tempering heat treatment in order to improve the mechanical characteristic and therefore its relevant performance. Avantages of fabricated girth gears

These features will reduce the lead time and costs. Fabricated manufacturing ensures a fast delivery. This is especially beneficial in an emergency situation, where the existing gear rim is suffering from damage Features

Forging material process

PinionsCITICIC Gear invested in significant resources and achieved

many innovations with pinions. The right combination of material,

hardness and finishing between pinion and gear is crucial for a

long lifetime of the installed equipment. We design and manufacture

pinions to match every customers need, no matter how unique the

situation might be.

Materialization

Characteristics

Standards/Certificates

Our pinions are applied in the cement and minerals industries:

Advantages

Rotary Kiln Girth GearsWe are leading supplier the Kiln Girth Gears for the various plants as listed below.

Gear Cutting Capacity:

The Kiln girth gears are available mainly in bi-part, four parts, 8 parts or multi segments as per the requirement and suitability with the application of gear.

In the field of grinding mill components, We supply mill heads,feed inlet,grinding roller,cement kiln riding ring, casting gears, shaft block .Also we supply mill shell of welding structures and fabrications.

Quality assurance documents Mill Girth Gear

Mill Girth Gear |

||||

| Product Tags: Large Ball Mill Girth Gear GS42CrMo4 Ball Mill Girth Gear 120 MT Mill Girth Gear |

|

Customized High Quality Cast Steel Ball Mill Pinion Gear Parts |

|

Customized 42CrMo Alloy Steel Hardened Gear Pinion Ball Mill |

|

Rotary Kiln And Ball Mill Gears High Load Bearing Capacity Stable Operation |

|

Large Casting Ball Mill Gear Ring Wear Resistant Stainless Steel |

|

Wear-Resistant Low-Noise Rotary Kiln Large Gear Ring Large Industrial Accessory |

|

Customized High Temperature Resistant Rotary Kiln Idler Roller Gear Ring Accessories |