Roller Crusher Mining Machine Spare Parts

|

|

Product Description

CITICIC is the leader in offering wear solutions to crusher

operators in China. We provide wear parts with designs and alloys

specifically developed for each application and specific location

within each crusher.Our crusher parts are made of manganese steel –

the toughest and most wear-resistant steel available. In

addition to the crusher components listed above, we also make cast

components for the crusher itself such as the pitman arm, side

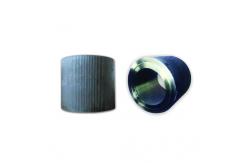

plates, cheek plates, etc. Roll Crusher Wearparts CITICIC produces Standard Roll Shells, although most customers choose our Oversize and Heavy Center Roll Shells because of the their longer life and resistance to caving. Smooth, Cleated and Corrugated surfaces are offered. Our standard manganese steel offers toughness and wear resistance with good weldability. We also produce Side Plates. Roller shell,made of wear resistant alloy raw material, processed from fine and heat treatment; √ Made of bearing steel, high hardness, good wearing resistance, long life, different tooth depth and shape at option;

√ Tooth surface forms of roller shell, good to pelleting performance

√ Frequently-used roller shell tooth form:honeycomb,scallop shape and scallop shape with edge banding

√ Honeycomb,scallop shape, the two types of roller shell is mainly used in livestock and poultry feed pelleting.

√ The advantage of honeycomb rolller shell is the even wearing of ring die, but coil performance is bad.

√ Scallop-shaped roller shell features good coil performance, widely used among feed mills, but wearing of ring die is not even.

√ Scallop shape with edge banding, this kind of roller shell is applicable for aquafeed. Feed is not easy to slide towards both sides when being extruded. GENERAL DESCRIPTION Wear components for crushing processes are subjected to severe

impact and high abrasion, requiring components made from impact

resistant and abrasion resistant alloys. We increase crusher availability through: • Increased wear life • Less on-going wear part maintenance • Designs and tools for quicker change out Our Services Aftersales service LUOYANG ZHONGTAI INDUSTRIES able to provide: 1. ENGINEERED SPARES - DESIGN AND MANUFACTURING 2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES 3. HUGE MACHINE SHOP CAPABILITIES 4. TRAINING PROGRAMMES 5. PREVENTATIVE MAINTENANCE PROGRAMS 6. PREVETATIVE MAINTENANCE SERVICES 7. COMPREHENSIVE MAINTENANCE PROGRAMS LUOYANG ZHONGTAI INDUSTRIES’s Field Service Engineers are trained specifically in the LUOYANG ZHONGTAI INDUSTRIES brand group products but are capable of undertaking the servicing of other OEM brands. Our technicians are equipped with the most advanced technological diagnostic equipment available to trouble shoot your equipment to optimise performance and minimise down time. LUOYANG ZHONGTAI INDUSTRIES also has an extensive capability in supplying all you consumable and electrical/ mechanical spare part needs. FAQ Q: Why we believe in luoyang zhongtai industries co., ltd: A: 1. More than 30 years experience. 2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts 3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time A: parts lead time 1-2months, machines 2-3months.

Q:Payment terms A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping

Q: Quality warranty? A: guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service? A: we can supply technical guide for machines running test and parts maintenance if end user needs. |

|

| Product Tags: Roller Crusher Spare Parts Ball Mill Mining Machine Spare Parts Roller Crusher Mining Machine Spare Parts |

|

High Level Rotary Kiln Support Roller Ball Mill With High Precision |

|

High Chrome Ball Mill Casting And Forging Steel Balls 20-150mm |

|

CITIC IC Raymod Mill Small Crown Pinion Gear Mining Machine Spare Parts |

|

high chrome ball mill casting and forging steel balls factory price and ball mill balls manufacturer |

|

Multi Layer Surfaces Grinding Welding Roller Of Mining Machine Spare Parts |

|

Customized High Quality High Manganese Steel Alloy Crusher Hammer Head For Mines |