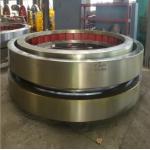

Forged Ring 65HRC Large Vertical Mill Ring Castings And Forgings

|

|

Forged Ring 65HRC Large Vertical Mill Ring Castings And Forgings Product Description

With more than 1000 girth gears sold over the world CITICIC Gear is a leading supplier in the cement and mineral industry. And as member of AGMA (American Gear Manufacturers Association), we do actively take part in defining the standard for gear rating calculations and service factors. We provide girth gears in three different designs Fabricated steel Cast steel Ductile (Nodular) cast iron

Fabricated gears became more common in the past and are constructed with forged steel gear rim materials and electro welded body structure. The rings are manufactured from a whole block of high resistance alloy steel. After the rough machining of the ring, we carry out hardening and tempering heat treatment in order to improve the mechanical characteristic and therefore its relevant performance. Avantages of fabricated girth gears The forged material structure excludes the risk of inclusions Structure defects like gas holes, micro shrinkage, pin holes, hot tears, sand and slag inclusions are avoided Hence, repair welding of the body structure and e.g. grinding of toothed areas is not required. The fabricated manufacturing procedure excludes the need for patterns and risers Rim material has higher hardness and higher strength than the material used for the underlying structure (i.e. web, gussets)

These features will reduce the lead time and costs. Fabricated manufacturing ensures a fast delivery. This is especially beneficial in an emergency situation, where the existing gear rim is suffering from damage Features External teeth

Internal teeth

PinionsCITICIC Gear invested in significant resources and achieved

many innovations with pinions. The right combination of material,

hardness and finishing between pinion and gear is crucial for a

long lifetime of the installed equipment. We design and manufacture

pinions to match every customers need, no matter how unique the

situation might be. bored solid on shaft / integral self aligned spur, helical or double helical Materialization forged alloyed steel through hardened, case hardened or quenched and tempered Spur, helical or double helical carburized induction nitrided Characteristics gear cutting with hobs the gear quality is checked by profile tester tooth flank modification designs /ratios according to ISO-DIN-A.G.M.A. FEM/FEA simulation software Standards/Certificates UNI EN ISO AWS ASTM ASME DIN Applications Ball - mills ROD - mills Semi Autogeneous Grind (SAG) Rotary kilns/coolers/dryers Advantages One Source Original Equipment Manufacture (OEM) Technical Drawings Gearing technical expertise for kilns and grinding mills State of the art manufacturing facilities and quality Global sales and service support |

|||||||||||

| Product Tags: Forged Large Vertical Mill Ring Steel Vertical Mill Ring CE Vertical Mill Ring |

|

Wear-Resistant Alloy Lining Plate Can Be Customized For Crusher And Ball Mill |

|

Long-Life Steel Balls With Good Toughness, Impact Resistance And Wear Resistance |

|

Customized Wear-Resistant High Chromium Alloy Lining For Ball Mill |

|

Rotary Kiln tyre For Enhancing The Rigidity Of The Cylinder |

|

Cost Effective High Quality And Customizable Steel Bolts |

|

High Temperature Resistant Slag Pot Casting Ladle Slag Transfer Container |