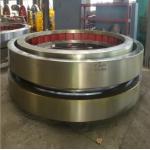

ball mill liners and Copper SAG Mill Liner and mill liner factory

|

|

Product Description

The company can be specialized in the production of citic heavy industry self - mill lining and luokuang self - mill lining, MZ series self - mill barrel lining. Its strong casting and forging, heat treatment and machining capacity, strict quality and process control methods, perfect testing and experimental means, so that its production and development of various wear-resistant products enjoy a high reputation in China, and sold overseas.

The structure and size of the liner are optimized by using the internationally recognized advanced liner simulation software.

The cylinder and the end cover liner are made of wear-resistant chromium-molybdenum alloy steel, and the convex liner is used to improve the service life and grinding effect.

The liner is fastened with a flat head bolt, matched with a self-locking nut and a sealing washer. Connection bolts have special sealing measures to prevent leakage of pulp.

The number of bolts fixing the lining plate is 5% rich.

Wear-resistant rubber filler strip is used in the joint of end cover liner plate and barrel body. They are fixed by close liner plate.

Rubber liner between cylinder and liner, 6mm thick, reduces noise.

|

||||||||||||||

| Product Tags: cylindrical Copper SAG Mill 1246 M3 Cylinder Copper SAG Mill 1000 tph SAG Mill |

|

Wear-Resistant Alloy Lining Plate Can Be Customized For Crusher And Ball Mill |

|

Long-Life Steel Balls With Good Toughness, Impact Resistance And Wear Resistance |

|

Rotary Kiln tyre For Enhancing The Rigidity Of The Cylinder |

|

High Temperature Resistant Slag Pot Casting Ladle Slag Transfer Container |

|

Wear-Resistant Slag Pot Mining Special Transfer Equipment High Temperature Resistant |

|

Customizable Welded Gear Reducer Housing Castings And Forgings |