Castings And Forgings For Eccentric Shaft Parts Of Jaw Crusher

|

|

Product Description Eccentric shaft for jaw crusher The main structure of jaw crusher is composed of main frame, movable jaw plate, fixed jaw plate, cheek plate, guard plate, eccentric shaft bearing, eccentric shaft, toggle plate, adjustment setting and so on. Among them there are some wear parts that need replacement. Generally speaking, jaw crusher spare parts are jaw plate, toggle plate, bearing and eccentric shaft.

Eccentric shaft function Jaw crusher eccentric shaft plays an quite important role in jaw crusher operating. The pitman is put in motion by the oscillation of an eccentric lobe on a shaft that goes through the pitman's entire length. This force is also put on the shaft itself so they are constructed with large dimensions and of hardened steel. The main shaft that rotates and has a large flywheel mounted on each end. Its eccentric shape moves the moving jaw in and out. Eccentric Shaft is machined out of Alloy Steel Fitted with anti-friction bearings and is housed in pitman and dust proof housing.

Jaw crusher eccentric shaft description: Shaft. Our products are developed using quality assured raw material and advanced technology in adherence with the internationals quality standards. These are highly acclaimed among our clients due to their superior quality and feasible prices.

Jaw crusher eccentric shaft features:

FQA Q: Why we believe in luoyang zhongtai industries co., ltd: A: 1. More than 30 years experience. 2.We are the leading professional supplier of mining machinery, construction machinery, machines casting and forged parts. 3. All products achieved ISO9901:2000 quality management certificate and CE, ROHS certificates.

Q:Delivery time : A: Parts lead time 1-2months, machines 2-3months.

Q:Payment terms : A: Accept payment type: T/T, L/C, Western union,Cash. 30% deposit when signed contract. Full payment paid before shipping.

Q: Quality warranty? A: Guarantee time: one year for main machinery. If something wrong we will provide the technical advice and find solution immediately. For those wearing parts we guarantee high quality parts for long-term supply.

Q: After sales service? A: we can supply technical guide for machines running test and parts maintenance if end user needs.

After-sales service LUOYANG ZHONGTAI INDUSTRIES able to provide: 1. ENGINEERED SPARES - DESIGN AND MANUFACTURING 2. LARGE VOLUME STEEL AND IRON CASTING FOUNDARIES 3. HUGE MACHINE SHOP CAPABILITIES 4. TRAINING PROGRAMMES 5. PREVENTATIVE MAINTENANCE PROGRAMS 6. PREVETATIVE MAINTENANCE SERVICES 7. COMPREHENSIVE MAINTENANCE PROGRAMS

|

||||||||||||

| Product Tags: Jaw Crusher Forgings Jaw Crusher Castings And Forgings Eccentric Shaft Castings And Forgings |

|

Mining Machine Castings And Forgings Of Table Of Vertical Mill Accessories |

|

Wear-Resistant Alloy Lining Plate Can Be Customized For Crusher And Ball Mill |

|

Long-Life Steel Balls With Good Toughness, Impact Resistance And Wear Resistance |

|

Customized Wear-Resistant High Chromium Alloy Lining For Ball Mill |

|

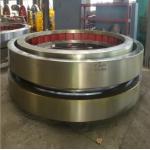

Rotary Kiln tyre For Enhancing The Rigidity Of The Cylinder |

|

Cost Effective High Quality And Customizable Steel Bolts |