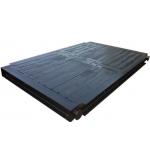

Polyurethane Oilfield Rig Mats Durable Lighter And Easy To Installation

|

Oilfield Rig Mats Polyurethane Durable Lighter And Easy To InstallationDrill floors require an extreme level of safety. Especially

securing friction on the deck is a high priority as mud, grease,

oil, water, etc, creates a very slippery milieu. |

| item | parameters |

| Break Strength / MPA | 50 |

| Elongation at Break. % | 550 |

| Hardness ( Shore A ) | 93 +/- 3 |

| Tearing Strength.Kn/m | 105.0 |

Main Features

1) Available in any color with identified danger zones.

2) Aggressive aggregate embedded to create traction enhanced surface.

3) Carton steel or SS nails embedded for added traction.

4) Very durable and resistant to fluids.

5) Channels on the surface allow for fluid runoff.

6) Custom service according to requirements.

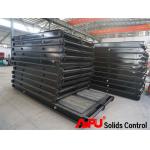

Oilfield drilling rig mats standard

The executive code includes wooden materials, hot rolled steel

beam, metal welding quality requirements, anti-corrosive wood,

drilling site layout, drilling equipment basic specification, and

so on

Suggested size including 5x2m, 3x2m, and 4x2m. 5x2m is suitable for

the base. The steel beam should be I beam larger than 16# or an H

beam larger than 175#. Wood material strength should be higher than

32.8MPa.

The wood beam on mats should be higher than the steel frame 10-20mm both upside and backside. Steel beam surface painting oil film thicks above 150microns. The welding quality should conform with GG/T12467.4 or equivalent

Oilfield drilling rig mats application

- Used as the equipment foundation for drilling rig, Triplex mud pumps, Mud tanks, Power rooms, SRC house, Oil tanks, Water tanks, in order to ensure the steadiness when the drilling equipment is placed at the drilling sites.

- Rig matting is suitable for all kinds of ground surfaces, especially for loose formation. Directly putting on the ground is available because of the large contact area, lower limits to the ground. When the ground loading capacity is≥06Mpa, and ground flatness ≤ 40mm, the rig matting can be working.

- It replaces the traditional concrete foundation, reducing the drilling costs, improving economic efficiency, and saving the land.

How to test and inspect oilfield drilling rig mats

Put the mattings on flat ground with strength loading over 0.15MPa.

Then lay materials on the mats gradually last 10 minutes. During

the whole, test check if any deformation or cracking on the rig

mats.

The spot inspection is based on 40 panels per batch. Each batch mat

should select 2 panels by chance. If any non-conformance happened,

there should be another check on the 2 panels again. If still any

non-conformance, we define this batch mats are not qualified.

We will deliver about 100 panels rig matting board to an African

oilfield drilling site. End-user requests strictly on whole quality

and inspection. They will despatch SGS people to inspect mats per

their requirements and agreement

Aipu oilfield drilling rig mats advantages

The raw material. Including the steel and the wood. Selected strictly according to executive code.

Wood will be processed under the anti-corrosion procedure.

We do the inspection and all processes step by step to ensure users' high-performance products.

Painting the rig mats with famous brand marine coating oil, which is high anti-corrosive.

Custom-built size and design as per clients' demand.

Aipu can produce rig mattings according to clients' certain requirements.