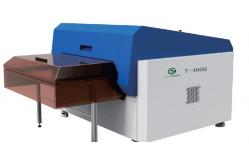

55 PPH Fully Automatic Thermal CTP System For Offset Printing

|

|

Full Automatic Thermal CTP Machine With 256-channel Laser Light Valve

Equipped with cutting-edge 256-channel laser light valve technology, this full-automatic thermal CTP machine achieves an exceptional output speed of 35–55 plates per hour for 8-up plates (1,030 × 800 mm, plate sensitivity: 100 mJ/cm²), delivering twice the productivity of previous-generation devices. By adopting square screen imaging technology, the system significantly enhances imaging performance, offering up to a 21% increase in color saturation and 10 times higher precision compared to conventional 200 LPI AM screening. This ensures sharper edges, richer tones, and superior dot clarity. The integration of a high-precision linear motor positioning system ensures stable performance, extended service life, and lower operational and maintenance costs, making it a highly efficient and reliable solution for modern prepress production environments.

Technical Specifications

Three kinds of plate loading ways for your option:

Technical Advantages

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Fully-Automatic Thermal CTP System 55 PPH Thermal CTP System Offset Printing Thermal CTP System | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

OEM 55PPH Newspaper Offset Printing Thermal CTP Plate Machine |

|

256CH Laser Head High Speed Offline Thermal CTP Machine |

|

FL4835 Polymer Cliche Plate CTP Machine For Flexo Printing |

|

CTP Flexographix Plate Image Making Machine |

|

Wide Format CTP Plate Processor Automated Developing Machine |

|

Aluminum Thermal CTP Plate Maker For Fast Short Run Offset Printing |