Non Ablation Thermal Negative CTP Printing Plates 0.15mm Thickness

|

|

Non-ablation Thermal Negative CTP Offset Printing Plate

Characteristics ECOO-G is a double layer, and the emulsion layer will not dissolve

in water, so it will not integrate into the fountain solution; while the protection layer is well water-soluble, and it will be easily dissolved into the fountain solution.

Specification

Model ECOO-G Plate Type Thermal-negative type Application High-grade commercial and newspaper printing Substrate Electrolyte graining and Anodized AL substrate Thickness 0.15mm/ 0.30mm Maximum short grain width Maximum width 1280 mm Spectrum scope 800-850 nm Photosensitive wavelength 830 nm Platesetter Various dominant thermal platesetters in the market Coating color Grey Low-energy imaging 130-150 mj/cm² The period of latent image stabilization ≤ 7 days Recommended screen method 1-99% @200 LPI AM or 20μm FM or mixture The paper number of start-ups < 50 sheets Safety light 4 hours under yellow light; 1 hour under fluorescent lamp; Direct exposure under natural light is safe but not recommended. Processing Without processing, directly on the press Run Length 100,000 impressions; Actual run length depends on printing conditions Shelf life 12 months under recommended condition Transportation Packed in seal and stored using prevention from light, moisture, overheating, and high humidity Storage Recommended condition: 18ºC-24ºC, 40%-50% RH.

Applied Parameters in Imaging Device

*Note: Higher exposure energy will make the image contrast clear,

and benefit to the plate run length; while over high/low exposure energy will

affect the image quality negatively.

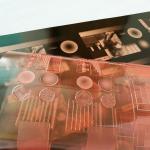

♠ Success Case

Producing And Packaging

♠ Certificates

♦ FAQ

Q1: Can I get the sample? A: We are very glad to provide some samples for you to test. We usually provide 5-15 pieces of plates for free, but sincerely hope to get your kind support for the air courier

freight. This cost can be returned to you in your first order. Q2: What is the cost for the CTP plate sample freight? A: The air freight depends on the packing size and weight, and the delivery destination. Or you can arrange the pick-up service from your local agent. Q3: How long can the sample be ready? A: It usually takes about 3 days to prepare the sample. Q4: Can I visit your factory? A: You are warmly welcome to visit our factory! Our company is in Hangzhou City, which is about 1.5 hours by train from Shanghai. Q5: How many square meters of CTP plates can feed one 20' container? A: About 20000-25000sqm. Q6: Can I take my brand and label on the packing? A: Yes, we can provide the OEM with the customer's brand and label. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Thermal Negative CTP Printing Plates 0.15mm Thickness CTP Printing Plates Non Ablation CTP Printing Plates |

|

Flexible Digutal CTP Printing Plates For Carton Packaging And Labels |

|

Black 2.84mm Photopolymer Digital Solvent Plate For Flexo Printing |

|

0.15mm Gauges Aluminum CTP Positive PS Plate Newspaper Printing |

|

Positive Writing Thermal CTP Printing Plates Double Layers |

|

Solvent Resistent Double Layer Thermal CTP Plate For Printing |

|

High Photosensitive Speed Aluminum CTP Positive PS Plate |