Label Embellishments Inkjet Digital Printer With UV Varnish And Foil Stamping

|

|

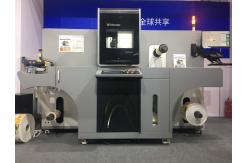

Label Embellishments Inkjet Digital Printer Foil Stamping And Varnishing Printing Machine

Product Description

EcooGraphix's newly developed EcooSpark digital printing machine

realizes digital synergistic processes such as digital varnishing, 3D crystal bright, partial glazing, cold foil

stamping, embossing, etc., without the need for plate making. lt can reduce costs and instantly realize unique visual effects of

printing. This is a digital post-press equipment thatcreates new

profit points for users, and is a digital efficiency-enhancing

printing machine. Features: Digital post-press enhancement technology can realize the superposition application of a variety of post-press processes, which is not easy to achieve in the previous traditional processes, such as spot varnish, embossing, foiling and other effects, and even can realize the superposition of a variety of color foiling, so that designers have more creative imagination space and add value for products. Washi tape is commonly made in a variety of decors, so EcooSpark is

widely used in the use of adhesive paper, beautify , decoration,

DIY and other purposes, such as luxury jewelry labels, wine labels,

cosmetic labels, W2P and other printing companies -Sturdy structure (double wall panel design) ;Thick and thin materials, stability, mature platform -High stability; Good material applicability; No heating required -LED UV+water cooling roller; Suitable for ordinary cold foil; High quality-details, sharp edges: -Less heat, higher stability; Patented technology-better detail performance -Multi-process completed at one time; Customizable Specification

Model: EcooSpark

Printing Technology: UV Piezo DoD-inkjet

Resolution: 360*360dpi, up to 1440*360 dpi

Printing speed: 6m/min - 50m/min(depend on polymer layer thickness)

Variable Image system: PDF, Optimized PDF, Optional barcode system

Supported image standards: PDF, PDF/VT, TIFF, JPEG, BMP & other data base files

Substrates: Offset, Digital, Plastics, Laminated and Coated Substrates

Printing image width: 288mm (extendable to 330 mm)

Polymer: WB-DS-Clear Polymer

Polymer layer thickness: From 10 up to 250 microns

Ink curing: Inter UV-LED Pre-curing/ Full curing by UV-LED

Unwinder diameter: Max. 700mm, Core 76mm

Rewinder diameter: Max. 700mm, Core 76mm

Substrates thickness: 30-400 micro

Substrates width: Max. 330mm Press with Foil station

Machine dimensions (LxHxW): 3500mm x 1900mm x 1800mm

Operating environment: Temperature: 15ºC-30ºC, Humidity: 40%-80% relative humidity

Electrical requirements: Voltage: 3x380, ±5% 3 phases +G+N; Frequency: 50/60 Hz;

Current: Avg. 58.6 Amps 23KW Weight: 2800kg

Advantage

EcooSpark enhancement printing machine mainly has the following advantages: Cost efficiency: There is no need for plate making, the setup time is shorter, and

it also has the cost advantage ofundertaking end user orders. Higher quality: High shining surface finish, can be repeatedly stacked, with variable foiling technology, etc, which canbe comparable to the traditional post-press process in the production process, and the registration accuracy is muchhigher than that of traditional printing technology. The "raise effect" or "embossing" effect is achieved by superimposedink lavers, and different heights can be stacked at the same time on the surface of the same substrate. Environment Friendly: ln addition to the short setup time, this is also manifested in terms of simpler operation and VDP design. Multi-process: High turnover rate, controllable and adjustable, reduce waste, foiling, convex foiling, spot varnishreverse varnish, Braille and other processes can be completed at one time. Using a piezoelectric inkiet head, a speciadigital UV varnish"la special formulation of transparent UV ink) is sprayed onto the substrate on demand to achieve spotvarnish, and the scope and shape of the varnishes are variable. At the same time, the highlight and matte effects can beachieved in a single printing. Regardless of whether the previous process is offset printing, gravure printing, flexographic printing or other printingEcooSpark can fully digitally realize spot varnish, cold foiling, embossing and other digital enhancement processes, withhigh efficiency, low cost, high added value and other advantages, can help enterprises quickly complete extremelyshort to medium length orders, instantly achieve the unigue visual effect of printing. In addition, the equipment can alsocooperate with traditional printing, digital printing and other post press processes to issue encounter by other processproblems, so as to find new profit growth points for printing enterprises. Effect of different thickness of foiling line on BOPP PP PET Art Coated paper Effect of different type of fonts

Foiling Workflow

Producing And Packing

FAQ

1. What are the postpress effects achieved by this machine? |

||||||||||||||||||||||||||||||||||||||

| Product Tags: Foil Stamping Inkjet Digital Printing Machine Label Embellishments Inkjet Digital Printer UV Varnish Digital Inkjet Printer |

|

Ecoospark UV Piezo Inkjet Label Roll Embellishment Machine Perfect Solution for Enhanced Effects |

|

High-Precision Inkjet Digital Roll To Roll Label Printer |

|

High Precision 1200dpix1200dpi Digital Inkjet Label Printing System |

|

10-160um Label Foil Stamping And Varnish Machine |

|

Digital Label Enhancement Foil Stamping And Varnish Finishing Machine |

|

Automatic Digital Label Foil Stamping And Varnishing Printing Machine Enhancer |