0.8um 15000pph Offset Printing Rubber Blanket For Coated Paper

|

|

Good Sale 15000pph 4/3Ply Press Rubber Blanket For Offset Printing Machine

⇒ 1 Application

EcooGraphix Printing Blanket is suitable for printing of coated papers, carton boards and the like. So the finish products of whole offset printing would be carton,

coated paper, newspaper, magazine and so on. ⇒ 2 Specification Model ECOO-BL-M Construction 4/3 ply fabric Thickness 1.97/1.70 ± 0.02mm Color Blue/ Green Compressible Microspheres Surface Micro-ground and polished Roughness 0.8-1.0μm Hardness 76-80 Shore A Elongation ≤ 1.0% Tensile Strength ≥ 85 Suitable Printing Segment Publishing, Packaging, Plastic and Metal Printing Application Strong universality; Appropriate to dot and word printing; Speed about 15000 prints/hour. Characteristic Moderate compressible avoids moving image of machine and reduces the edge marking. Wide-ranging print. Prefer to carton print and full mold print.

⇒ 3 Features

♥ High cost-effective. Our most economic blanket model as well as

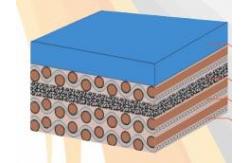

most popular seller, could satisfy 85% printing jobs. ♠ High compressive ability, which allows many types and printing material in different thickness. ♦ Wide range printing, prefers package printing on carton in moderate speed. ♣ Be excellent in the action of absorbing a shock such as a mechanical impact. ♥ Prevent the material to be printed from winding around the blanket cylinder. ⇒ 4 Structure And Aluminum Bar Structure The printing blanket normally includes 3 layers as below: A: a base non-woven fabric or a spun bonded non-woven fabric layer which is assigned to the printing cylinder; B: a soft, highly resilient void-free compressible intermediate rubber layer which has closed gas pores; C: an outer-lying void-free layer of an elastomeric layer which faces toward the printing material.

Aluminum Bar

We can offer blanket with or without bar, depending on customers'

inquiry. $5 will be surcharged for each pair of bars. Please let us know the machine model or bar size if you need blanket with bars.

⇒ 5 Packaging And Maintenance

The customer can decide the content of back side, usually the logo or size.

Blanket In Sheet

Blanket In Roll

Maintenance

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

⇒ 6 Tips

2) How does it work ?

Simply speaking, the blanket is to transfer the image from plate

onto paper.

⇒ 7 Certificates

⇒ 8 FAQ

Q1: Do you offer free sample ? How long is the sample time of the shipping ? Does the sample fee can be returned ? A: Since blanket is high value, we did not offer free sample. But we can offer favorable discount. It will take 5 days to prepare sample. If you place formal bulk order, we will refund the sample fee and courier cost.

Q2: About the sample what is the cost of transportation ? A: The freight depends on weight, packing size and your country or province region, etc.

Q3: How long can I expect to get the sample ? A: The sample will be ready for delivery in 3-5 days and will be sent via international express such as DHL, UPS, TNT, FEDEX and would be arrived within 3-5 days.

|

||||||||||||||||||||||||||

| Product Tags: 15000pph Offset Printing Rubber Blanket 0.8um Offset Printing Rubber Blanket Coated Paper Printing Rubber Blanket |

|

60ML/Hour CTP Thermal Plate Developer For Offset Printing |

|

Sodium Gluconate CTP Thermal Plate Developer for Offset Printing |

|

Positive UV CTP Thermal Plate Developer Chemistry For Offset Printing |

|

CTP Thermal Plate Developer Sodium Gluconate For Offset Printing |

|

Sodium Gluconate CTP Thermal Plate Developer for Offset Printing |

|

120ML/SQM Positive UV CTP Thermal Plate Developer for Offset Printing |