0.8Mpa 350M/Min Cross Paper Cutting Machine 1500mm Stacking

|

|

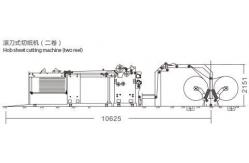

350 M/Min Cross Cutting Servo Precision Paper Sheeter Cutting Machine

※ Features Introduced

※ Specifications

High-Speed Inkjet Digital Press

ECOO GM-1400

The up knife cut reciprocally and the down knife is fixed

60-550g

1800mm

1400mm

450-1600mm

2 sheet

Cutting length≤ 1000mm: ±0.5mm, Cutting length> 1000mm: ±0.1%

350 cut/min

350 m/min

1500mm

0.8Mpa

380V/220V 50HZ

13000KGS Cutting Precision: Depending on the density, roll number and material of paper roll, ±0.5mm for 1000mm, ±0.1% for over 1000mm, and ±0.1% for acceleration or deceleration. The above data is based on the stable cutting operation and correct operation procedure. (When the cutting paper roll is one, the length of the cutting paper is the correct length)

Output: Actual output depends on the paper material, paper weight, cutting length, number of paper roll, technology of the operator and operation conditions, etc.

※ Standard Configurations

① High-precision single knife cutting machine ② Auto prismatic adjustment system for paper ③ Middle slitting and waste collection paper system ④ Automatic counting and label inserting equipment ⑤ Paper transporting equipment ⑥ Automatic paper trimming and collecting machine ⑦ Electrical controlling system ⑧ Driving motor system ⑨ Accessory by machine ⑩ Double arm oil pressure shaftless mill roll stand ⑪ Equipment of electrostatic elimination ⑫ Automatic directing and paper tension controller ⑬ Equipment of automatic vacuum ⑭ Operation system: LCD panel by operator ⑮ Main drive system: AC servo motor

※ Producing And Packaging

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

※ Certificates

※ FAQ

Q1: What are your main products ? A: Our main products are the Prepress 4up and 8up Online/Offline

Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates,

Offset Inks, Offset Printing Blankets, Postpress Packing Equipment

and so on. You can get the equipment and consumables all in one and no worry

about the after-sales service from our company.

A: Our CTP processor machine factory is in Shanghai, you are warmly

welcome to visit our factory!

A: Three years' laser head and main spare parts for the CTPs, one year

for the processor.

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.

A: Our engineer can go to help the installation and provide the necessary training. The buyer should take the round air plane tickets, service charge and the local accommodation cost. Any problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are also many end users(printers) who have purchased the CTP products from EcooGraphix China directly and EcooGraphix technical service team support these installations remotely with regular onsite visits.

These end users printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction.

|

||||||||||||||||||||||||||||||

| Product Tags: 350M/Min Cross Paper Cutting Machine 0.8Mpa Cross Paper Cutting Machine 1500mm Stacking Paper Cutting Machine | ||||||||||||||||||||||||||||||

|

ECOO T-1400C 1400mm Shaftless ATM Thermal Paper Roll Slitter Rewinder 1400mm |

|

1400C Shaftless Thermal Paper Slitting Machine 1400mm Unwinding Width |

|

1400mm Thermal Paper Slitting Rewinding Machine For Fax Cash Register ATM ECG POS Till Kraft Paper Rolls |

|

1400mm Thermal Paper Slitting Rewinding Machine for Fax Cash Register ATM ECG POS Till Kraft Paper Rolls |

|

ECOO-T1400FA Shaftless Hydraulic Loading Thermal Paper Slitting Rewinding Machine |

|

ECOO-T1400FA Shaftless Hydraulic Loading Thermal Paper Slitting Rewinding Machine |