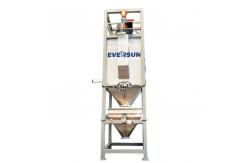

Closed Bag Dump Station Bulk Material Discharging Unpacking Machine

|

|

Product Introduction

Bulk material discharging machine is mainly used for continuous unpacking of 500-2500kg ton bag materials, to achieve ton bag conveying, automatic unpacking, waste bag automatic packaging and other automatic production line, the production line is high degree of automation, fast unpacking speed, without manual participation.

The bulk material discharging machine is lifted to the feed port of the equipment by the electric hoist, the bulk material discharging port is opened manually, the flow valve is opened and assisted by the vibration device to make the powder and granular materials in the ton bag fall into the cache tank by gravity to complete the unpacking and unloading work. Large bag opening station replaces traditional manual unpacking, clean production environment, no dust leakage. It is mainly used for unpacking and unloading tons of granular and powdery materials, such as feed, seeds, food, chemical raw materials, condiments, medical raw materials, etc.

Product Aavantages 1. The structure of bulk material discharging machine is simple and reasonable, and the operation is convenient.

2, the use of anchor chain electric hoist, simple structure, flexible and convenient operation.

3. Replace traditional manual unpacking and improve production efficiency.

4. Entrainment device ensures no dust leakage during unloading.

5. Beating device can better ensure smooth discharge, prevent material retention.

6. The configuration of dust removal interface, connected with the user dust removal system, dust collection, protect the site environment clean health.

7. 1) After the unpacking of tons of bags, the materials can be integrated into unpacking and feeding through pipe chain conveyor, screw conveyor, pneumatic conveying system and other conveying equipment. 2) The waste bags after the ton packing machine can be matched with the waste bag packing robot to realize the automatic collection, strapping and packing of waste bags. Can also take the manual unpack bag, reuse the bag.

Operation process Operation process of bulk material discharging machine: 1. The electric hoist in the equipment is lifted and fixed on the beam of the body, and the bracket is fixed at the same time to achieve the ideal working effect.

2, tons of bag by electric hoist, to the top of the hopper, bag mouth into the hopper inlet, and then close the bag valve, open the bag mouth, and then let the material in the bag smoothly into the hopper, so as to achieve dust-free operation, ensure the quality of materials.

3. The material falls to the rotary valve at the bottom through the hopper, so as to enter the specified equipment, or the vacuum conveying pipe is connected at the bottom of the equipment, and the material is transferred to the specified position by sealing.

4. The dust collector will filter out the dust produced, and the clean tail gas will be discharged into the atmosphere, so that the operator can work in a clean and tidy environment. |

||||||||||||||||

| Product Tags: Closed Bulk Bag Discharging Station Unpacking Bag Dump Station Stainless Steel 304 Bag Dumping Station |

|

Sealed And Eco-friendly Bulk Bag Unloader For Powder And Granular Material Handling In Industries |

|

Open Bulk Bag Unloader For Smooth Material Transfer And Unloading In Chemical Grain And Building Material Industries |

|

Practical And Low-Maintenance Bulk Bag Unloader For Fast And Even Discharge Of Granular And Powdered Materials |

|

Environmentally Friendly Material Handling Bulk Bag Unloader with Sealed Feeding and Dust Control |

|

Intelligent Control Bulk Bag Unloader for Dust-Free and High Cleanliness Feeding in Chemical and Pharmaceutical Industries |

|

Sealed Structure And Negative Pressure Bulk Bag Unloader For Dust Control Clean Feeding In Industries |