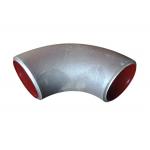

Seamless Pipe Fittings ASTM Forged Butt Welding Carbon Steel Pipe

Fitting Elbow -

- Seamless elbow technology:

Carbon steel seamless elbow forming technology is to choose the

special elbow pipe parts of the push machine, core mold and heating

equipment, so that the blank on the mold in the push machine to

move forward, in the movement of heating, expanding and zigzag

forming process.Hot pushing elbow pipes deformation characteristics

is based on volume before and after plastic deformation rule of

metal materials concluded that tube billet diameter, chooses the

pipe diameter is less than the diameter of the elbow pipe fittings,

through core model control billet deformation process, the arc is

tight spot metal activity, counter to other parts of the thinned by

expanding, then get the uniform wall thickness of elbow pipe

fittings.Hot push pipe fitting forming technology has the

characteristics of beautiful appearance, uniform wall thickness and

continuous work, suitable for mass production, so it has become the

primary forming method of carbon steel, alloy steel and carbon

steel elbow, and also applied in the forming of some standard

stainless steel elbow pipe fitting.The heating methods of the

forming process include medium frequency or high frequency

induction heating (heating ring can be multi-turn or single turn),

flame heating and reflective furnace heating. The choice of heating

methods depends on the demand of the forming commodity and the

power status of the decision.

Seamless elbow manufacturers -

| ASTM Forged Butt Welding Carbon Steel Pipe Fitting Elbow | | Standards | ASME/ANSI B16.9, ASME/ANSI B16.11, ASME/ANSI B16.28,JIS B2311, JIS

B2312, DIN 2605, DIN 2615, DIN 2616, DIN 2617, BS 4504, GOST 17375,

GOST 30753, GOST 17378 | | Bending radius | Short Radius(SR), Long Radius(LR), 2D, 3D, 5D, multiple | | Degree | 45 / 90 / 180, or customized degree | | Size Range | Seamless type: ½" up to 28" | | Welded type: 28"-to 72" | | WT Schedule | SCH STD,SCH10 to SCH160, XS, XXS, | | Carbon Steel | A234 WPB, WPC; A106B, ASTM A420 WPL9, WPL3, WPL6, WPHY-42WPHY-46,

WPHY-52, WPHY-60, WPHY-65, WPHY-70, | | Alloy Steel | A234 WP1, WP11, WP12, WP22, WP5, WP9, WP91 | | Special Alloy Steel | Inconel 600, Inconel 625, Inconel 718, Inconel X750, Incoloy 800, | | Incoloy 800H, Incoloy 825, Hastelloy C276, Monel 400, Monel K500 | | WPS 31254 S32750, UNS S32760 | | Stainless Steel | ASTM A403 WP304/304L, WP316/316L, WP321, WP347, WPS 31254 | | Duplex stainless steel | ASTM A 815 UNS S31803, UNS S32750, UNS S32760 | | Applications | Petroleum industry, chemical, power plant, gas piping,

shipbuilding. construction, sewage disposal,and nuclear power etc. | | Packaging material | plywood cases or pallets, or as per customer's requirements | | Production Period | 2-3weeks for normal orders |

-

|